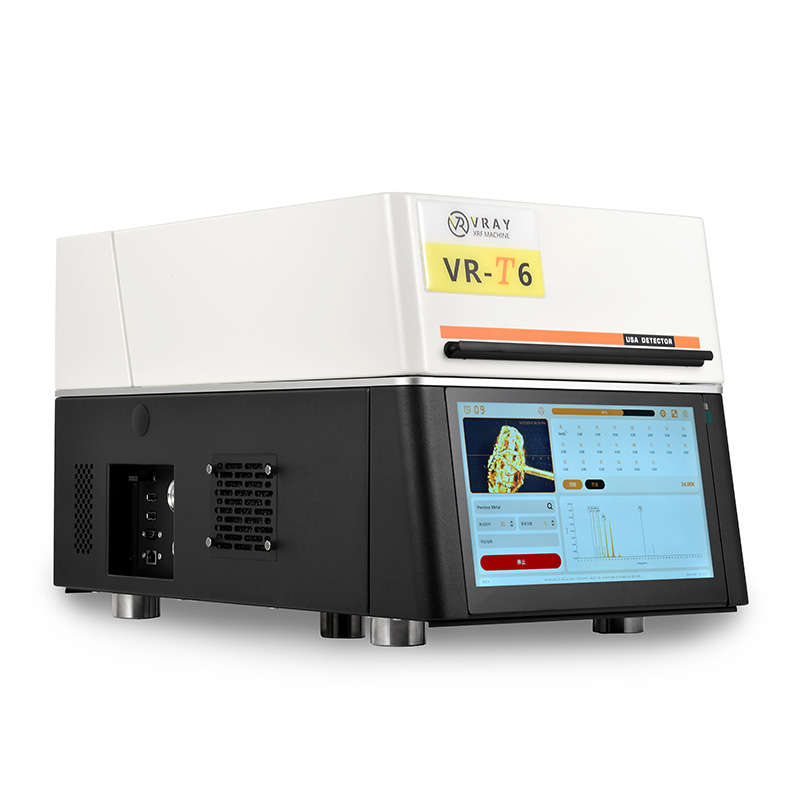

With 17 years of dedicated manufacturing experience, VRAY delivers comprehensive XRF metal analyzer solutions tailored to various industries. Our diverse product lineup includes the highly portable VR-M5 and robust desktop models like the VR-T6 and VR-X3, each engineered for specific analytical needs.

Our XRF metal analyzers boast advanced features and core technologies. Models like the VR-M5 and VR-T6 feature Customized Si-Pin Detectors from the USA, ensuring superior accuracy (e.g., 0.03% for 9999 gold on VR-T6, 0.05% on VR-M5) and rapid 30-second test times for solids, liquids, and powders. The more economical VR-X3 utilizes a Gas Proportional Detector, offering reliable 0.1% accuracy for 999 gold in 50 seconds, ideal for solid precious metal identification. All models benefit from powerful 50W micro-focused tungsten X-ray tubes and efficient T-shaped radiators for stable performance. Advanced features like 11.6" touchscreens (VR-T6), inbuilt i5 Windows 11 computers (VR-T6), 5.7" retractable screens (VR-M5), and built-in 5MP cameras (VR-M5) enhance usability and data management.

VRAY provides flexible customization options to perfectly match your requirements. Hardware can be tailored, including detector type, X-ray tube power, target material, and collimator size. Software customizations cover analysis modes, calibration algorithms, multi-language interfaces, and custom report formats. This commitment to customization ensures our XRF metal analyzers are optimized for your unique applications.

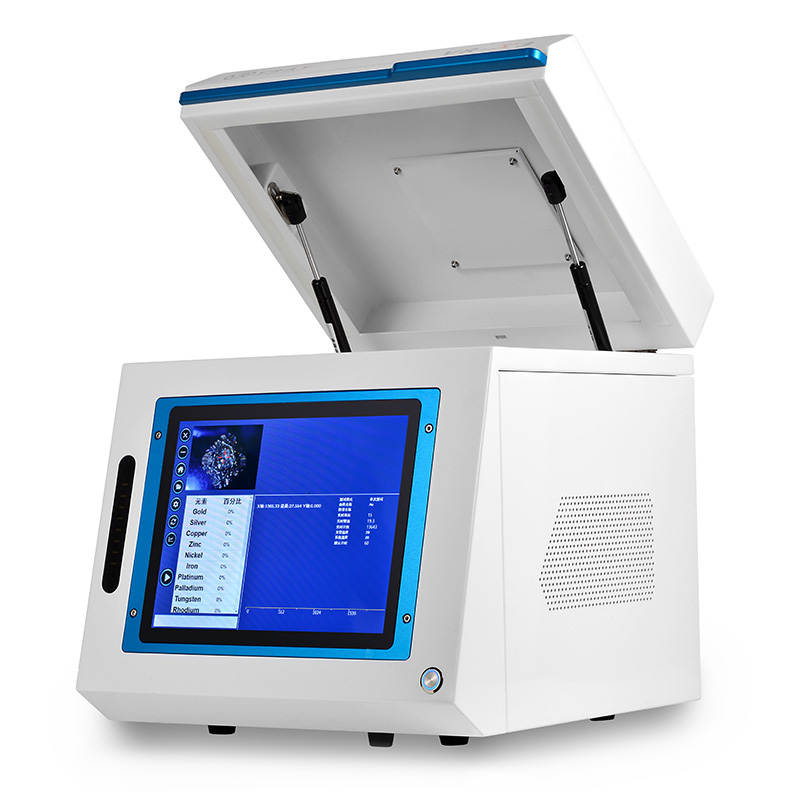

The XRF metal analyzer works by emitting a primary X-ray beam onto a sample. This excites atoms within the sample, causing them to emit unique "secondary" or "fluorescent" X-rays. Each element produces characteristic X-rays, like a fingerprint. The analyzer's detector measures the energy and intensity of these emitted X-rays, allowing it to determine the specific elements present and their concentrations. This process is non-destructive, meaning it won't damage the sample.

XRF metal analyzer helps customers solve crucial problems related to material composition. They provide rapid and precise material verification and quality control, ensuring products meet specifications. For the jewelry and recycling industries, they offer accurate precious metal assaying and purity determination, combating fraud and ensuring fair valuation. This technology delivers high accuracy, efficiency, and reliability, preventing costly material mix-ups and streamlining workflows.

XRF metal analyzers are highly versatile instruments capable of non-destructively identifying and quantifying a wide range of metallic elements. They utilize X-ray fluorescence to provide rapid and precise material composition analysis. VRAY's analyzers, including portable and desktop models, deliver exceptional precision, making them indispensable across various industries from jewelry to industrial quality control.

Aspect | Details |

Metals/Elements Tested | From Potassium (K) to Uranium (U), including precious metals (Au, Ag, Pt, Pd), base metals (Cu, Fe, Ni), alloys, and trace elements. |

Precision & Accuracy | High Precision: Varies by model/detector. VRAY's Si-Pin models (e.g., VR-S6, VR-T6) achieve 0.03% accuracy for 9999 gold. VR-M5/VR-X5 offer 0.05% accuracy. VR-X3 provides 0.1% for 999 gold. |

Influencing Factors | Detector type (Si-Pin vs. Gas Proportional), X-ray tube power, test duration, and calibration quality. |

What did our happy clients say?

Recently bought the VRAY VR-M5 XRF metal analyzer. Its 4.1Kg weight and 0.05% (9999 gold) accuracy are perfect for field work. The 5.7" screen and 30s test are brilliant. Works from -20℃ to 50℃! Highly recommend this portable powerhouse for anyone on the go.

Our VRAY VR-T6 XRF metal analyzer is incredibly precise. With 0.03% accuracy for 9999 gold and 30s tests, it's a lab workhorse. The 11.6" Windows 11 touchscreen is so intuitive. It's truly a top-tier instrument. Don't hesitate to invest in this for ultimate accuracy!

Thrilled with my VRAY VR-X5 XRF metal analyzer. The 0.05% accuracy for 9999 gold and K-U element range are fantastic. It handles solids, liquids, and powders flawlessly in 40s. A truly versatile and reliable machine for any material analysis. Strongly recommended for diverse labs!

We love our VRAY VR-X3 XRF metal analyzer! It gives 0.1% accuracy for 999 gold in 50s, which is excellent value. Reliable for precious metals (Au, Ag, Cu, Pt, Pd, Ir, Cd). This cost-effective desktop unit is a must-have for small businesses. Definitely buy this model!