VRAY delivers advanced jewelry testing machine solutions leveraging cutting-edge X-ray Fluorescence (XRF) technology for precise, non-destructive precious metal analysis. Our diverse portfolio ensures unparalleled accuracy and efficiency for professionals.

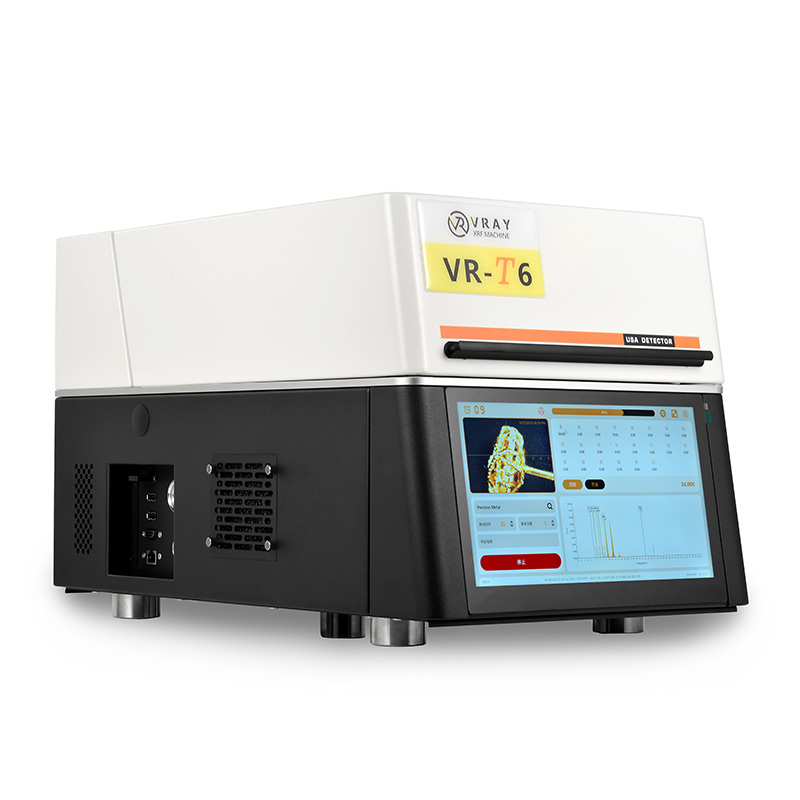

VRAY VR-S6 (Mini Desktop): Compact with 0.03% accuracy for 9999 gold (solids/liquids/powders), 30s test. Features USA-sourced Si-Pin detector and 11.6" touchscreen.

VRAY VR-H5 (Mobile-first Handheld): Portable, 0.03% accuracy for 9999 gold (solids/liquids/powders), 30s test. USA Si-Pin detector, 8-hour battery, wide -20℃~50℃ range. (1.6Kg).

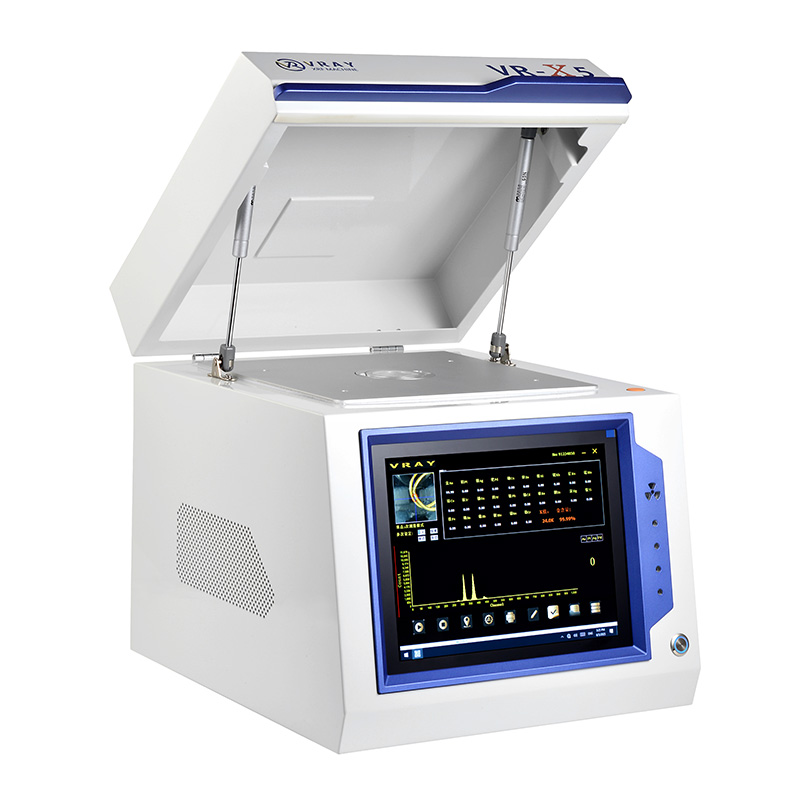

VRAY VR-T7 (High Precision Desktop): Flagship, industry-leading 0.01% accuracy for 9999 gold. High-sensitivity SDD detector, micro-focused beryllium tube, manual XY platform, 5MP camera (40x-160x magnification) for detailed 30s analysis.

All VRAY jewelry testing machine models feature powerful 50W micro-focused X-ray tubes and T-shaped radiators for safe heat dissipation, eliminating external cooling. Integrated computers ensure intuitive operation. Our solutions guarantee rapid, reliable, and exceptionally accurate precious metal testing for all professional applications.

Advanced X-ray Tubes: Our machines utilize powerful 50W (50 kV, 1mA) micro-focused tungsten X-ray tubes. The VR-T7 even features a beryllium window tube for enhanced precision. These tubes efficiently generate the primary X-ray beam necessary for elemental excitation.

High-Performance Detectors: VRAY employs various high-quality detectors:

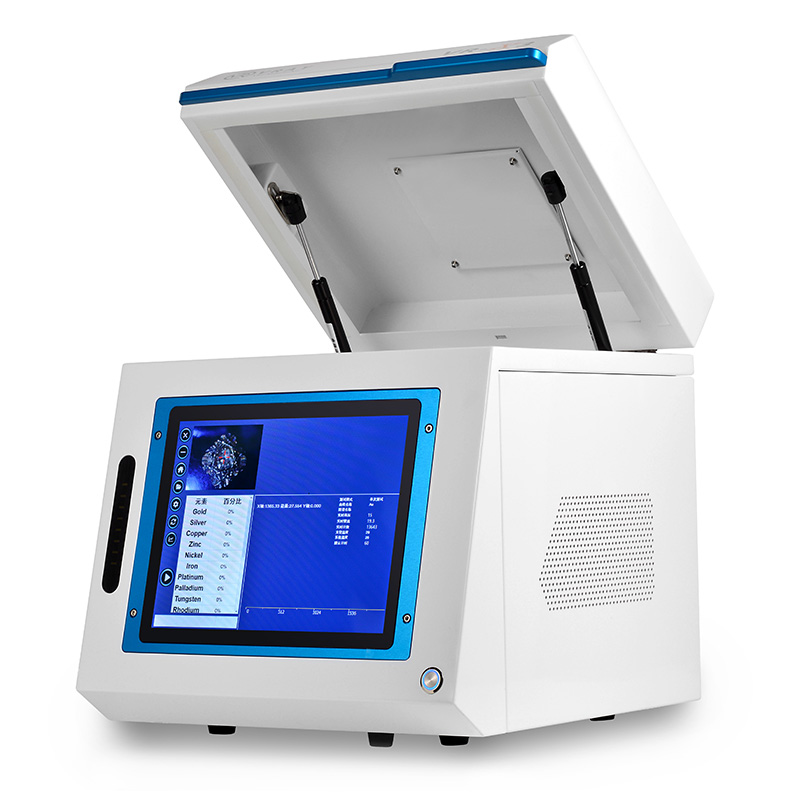

Gas Proportional Detector: Found in models like the VR-X3, providing reliable accuracy for common gold testing.

Customized Si-Pin Detectors: Present in VR-S6 and VR-H5, often sourced from the USA, offering enhanced sensitivity and 0.03% accuracy for 9999 gold.

High Sensitivity SDD Detector: Featured in the top-tier VR-T7, enabling exceptional 0.01% accuracy for 9999 gold.

Precise Collimation: A ϕ2.5mm collimator (or ϕ1.5mm in VR-T7) focuses the X-ray beam, ensuring accurate targeting of the sample.

Integrated Computing & Software: All desktop models include powerful built-in industrial computers (e.g., Intel i5, Windows 11) for seamless operation, data processing, and result display via touchscreens.

Efficient Heat Management: A dedicated T-shaped radiator system efficiently dissipates heat, eliminating the need for external cooling and ensuring stable, continuous operation while enhancing safety.

Enhanced Features (Select Models): The VR-T7 boasts a manual XY platform for precise sample positioning and a 5-megapixel CMOS camera with 40x-160x magnification for detailed visual inspection. The VR-H5 offers unique portability with an 8-hour intelligent battery and broad operating temperature range (-20℃~50℃).

VRAY's Jewelry Testing Machines cater to diverse professionals requiring reliable and rapid analysis:

Jewelers and Retailers: Enable on-the-spot, non-destructive verification of gold karat and precious metal composition, building customer trust and facilitating quick transactions.

Appraisers and Valuers: Provide highly accurate elemental analysis for precise valuation of jewelry, including complex alloys and varying forms (solid, liquid, powder).

Pawn Shops: Offer fast and accurate assessment of precious metal collateral, streamlining operations.

Manufacturers and Refiners: Support quality control by verifying material purity throughout production and for efficient processing of scrap metals.

Anti-Fraud Efforts: Crucial for identifying misrepresented items or detecting counterfeit materials, protecting investments and reputation.

Mobile Professionals: The handheld VR-H5 allows for accurate testing in diverse field conditions, expanding service reach.

Model | Type & Primary Function | Price Range (USD) |

VR-S6 | Mini Desktop Gold Tester | $12,000 - $14,000 |

VR-H5 | Mobile-first Handheld Gold Tester | $15,000 - $18,000 |

VR-T7 | High Precision Desktop Gold Tester | $20,000 - $22,000 |

Installation Instructions

Software update

Technical training

Hardware warranty

Remote guidance

Ensuring the safe and accurate performance of your Jewelry Testing Machine requires strict adherence to operational guidelines and an awareness of potential hazards.

Power on the machine and open the software.

Preheat the instrument for 10 minutes.

Calibrate the instrument daily with the provided calibration sample upon its first use.

Place the sample in the detection area, then strictly close the protective door before pressing "start" to test.

Wait for the result; preliminary analysis displays in 3 seconds, complete results in 30 seconds. You can then print an A4 or Bluetooth report, or save it.

It's recommended to use a regulated power supply or UPS to prevent damage from voltage fluctuations.

Keep the working environment dry, clean, and well-ventilated, avoiding high temperature and high humidity.

Always follow the operation manual and manufacturer's training guidelines; do not modify parameter settings privately.

Starting a test when the protective door is not tightly closed can cause X-ray leakage and radiation damage to the operator.

Forcibly cutting power or frequently turning the machine on/off can damage the X-ray tube, high-voltage module, or hard disk, leading to system crashes.

Operating in humid, hot, or dusty environments can cause overheating, mainboard dampness, and detector malfunction or short-circuit.

Unauthorized modification of software parameters or calibration data may cause data distortion, potentially requiring the software to be returned to the factory for recalibration.

Touching the detector window with sharp objects or fingers will damage the detector film, resulting in extremely high maintenance costs.

Moving the sample or opening the door during a test can cause the sample position to shift, leading to test failure and X-ray exposure.

What did our happy clients say?

The VRAY VR-T7 Jewelry Testing Machine is phenomenal! Its industry-leading 0.01% accuracy for 9999 gold and high-sensitivity SDD detector are top-notch. The ϕ1.5mm collimator and 5MP camera enhance precision. Absolutely essential for top-tier labs.

The VR-H5 Jewelry Testing Machine is perfectly portable! Delivering 0.03% accuracy for 9999 gold on-site, its 1.6Kg weight and 8-hour battery are key. The wide -20℃~50℃ operating range makes it truly versatile. Highly recommended for mobile appraisers.

This VRAY VR-S6 Jewelry Testing Machine is fantastic for daily use. It offers 0.03% accuracy for 9999 gold and fast 30s tests with a USA-sourced Si-Pin detector. The 11.6" touchscreen makes operation effortless. Excellent value for our retail store.

Our VRAY Jewelry Testing Machine (like my VR-S6) offers impressive reliability. The 50W micro-focused X-ray tube and T-shaped radiator ensure consistent performance and safety. Their support, including remote guidance, is also top-notch. A trustworthy investment.