VRAY offers advanced XRF Precious Metal Analyzer solutions, delivering precise, non-destructive elemental analysis for the jewelry and precious metals industry. Our range includes versatile portable and high-performance desktop models.

Our Portable VR-M5 (4.1Kg), offers 0.05% accuracy for 9999 gold with a 5.7" retractable touchscreen and 5MP camera, priced at $15,000-$18,000.

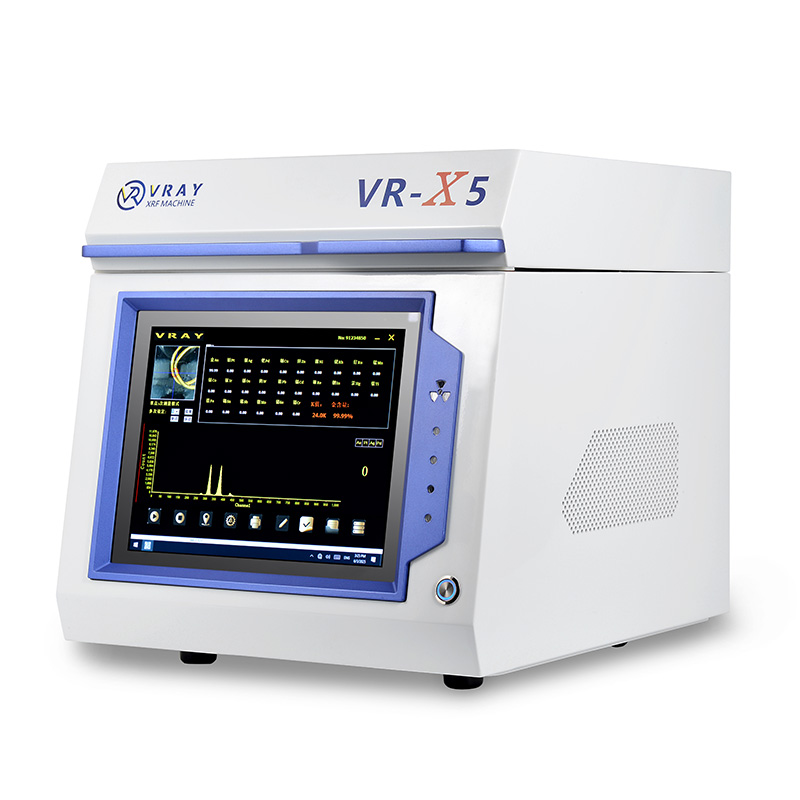

For Desktop operations, the VR-X5 provides 0.05% accuracy for 9999 gold (K(19)-U(92) elements, 40s test, Intel i5) at $10,000-$11,000. The flagship VR-S7 sets a new standard with 0.01% accuracy for 9999 gold, featuring a high-sensitivity SDD detector, ϕ1.5mm collimator, and i5-1035G7 Win11 for $20,000-$22,000.

All analyze solid/liquid/powder samples. Core tech includes 50W micro-focused X-ray tubes, customized Si-Pin/SDD detectors, and T-shaped radiators for safe heat dissipation. VRAY provides tailored solutions for professional precision.

VRAY's XRF Precious Metal Analyzers are equipped with advanced features for superior performance:

High Accuracy: Ranging from 0.01% for 9999 gold (VR-S7, VR-T7) to 0.03% (VR-H5) and 0.05% (VR-X5, VR-M5).

Rapid Analysis: Most tests complete within 30-50 seconds.

Versatile Sample Testing: Capable of analyzing solid, liquid, and powder samples (VR-X3 handles solids only).

Advanced Detectors: Utilize high-performance Customized Si-Pin and High-sensitivity SDD detectors for precise measurement.

Robust X-ray Source: Features a 50W micro-focused X-ray tube (tungsten or beryllium window).

Efficient Heat Management: Equipped with a dedicated T-shaped radiator ensuring stable operation without cooling delays.

User-Friendly Interface: Operated via intuitive touchscreens and powered by built-in industrial computers (e.g., Intel i5, Windows 11).

Portability & Design: Available in ultra-light Handheld (VR-H5 at 1.6Kg with 8hr battery) and Portable (VR-M5 at 4.1Kg) versions, alongside various desktop models.

Enhanced Capabilities: Some models include 5MP high-definition cameras and manual XY sample platforms for detailed inspection and targeted analysis.

The primary functions of an XRF Precious Metal Analyzer are:

Elemental Composition Determination: Identifies and quantifies the specific elements present in a sample, capable of detecting elements from K(19) to U(92) in advanced models.

Purity/Karatage Assessment: Precisely calculates the purity of precious metals (e.g., gold karat, silver fineness, platinum percentage).

Non-destructive Testing: Performs analysis without damaging or altering the sample, making it ideal for finished goods.

Material Authentication: Verifies the authenticity of precious metal items, differentiating genuine articles from fakes or alloys.

Quality Control: Ensures consistent material composition and purity in manufacturing and refining processes.

Quantitative Analysis: Provides accurate percentages or concentrations of each detected element.

Operating an XRF Precious Metal Analyzer follows a systematic procedure, ensuring accurate and safe results:

Power On & Software Launch: Turn on the analyzer and launch its dedicated analysis software.

Preheat & Calibrate: Allow the instrument to preheat (approx. 10 minutes). Before the first test of the day, perform a daily calibration using the certified calibration sample, following the on-screen prompts.

Sample Placement: Carefully place the sample (solid, liquid, or powder) into the analyzer's test chamber.

Secure & Start Test: Crucially, ensure the protective door of the chamber is securely closed. Then, initiate the test via the software interface or "start" button.

Result Acquisition: The analyzer will perform the test (typically 30-50 seconds) and display the elemental composition and purity results on the screen.

Data Analysis & Reporting: Review the results, which often include element percentages or karatage. You can then print a detailed report or save the data digitally for records.

Safety Reminder: Never open the chamber door or move the sample during an active test to prevent X-ray exposure.

XRF Precious Metal Analyzers are essential across various sectors due to their speed and non-destructive nature:

Jewelry Industry: Used for appraisal, valuation, and quality verification of gold, silver, platinum, and palladium jewelry.

Purity Testing: Critical for verifying the fineness of precious metals in coins, bullion, and ingots.

Fraud Detection: Key in identifying counterfeit items, distinguishing real gold from plated or alloyed materials.

Scrap Metal Recycling: Efficiently sorts and analyzes precious metal scrap for optimal recovery and recycling.

Manufacturing & Refining: Employed for quality control of raw materials and finished products, ensuring consistent standards.

Pawn Shops & Retail Stores: Enables on-the-spot, reliable testing for buying, selling, and authenticating items.

Customs & Border Control: Used for quick verification of declared metal contents in imports and exports.

Geological & Mining: For preliminary analysis of samples containing precious metals.

The price difference primarily reflects enhanced performance and specialized features. The VRAY VR-X5 ($10,000-$11,000) offers excellent value as a versatile desktop analyzer with 0.05% accuracy for 9999 gold, a broad K(19)~U(92) elemental range, and an efficient 40-second test time. It's ideal for general jewelry testing, quality control, and retail environments where robust, reliable performance is needed. The VRAY VR-S7 ($20,000-$22,000), on the other hand, is a flagship lab-level instrument with 0.01% accuracy for 9999 gold. Its higher price is justified by a superior High-sensitivity SDD detector, a finer ϕ1.5mm collimator for enhanced precision, faster 30-second test times, and a more advanced i5-1035G7 Windows 11 internal computer. The VR-S7 is suited for demanding laboratory research, refining, or situations requiring the absolute highest level of accuracy and detailed elemental analysis. The "value" depends on your specific accuracy requirements and budget; for most commercial uses, the VR-X5 offers superb capability, while the VR-S7 targets precision-critical applications.

Sustaining the high accuracy (e.g., 0.01%-0.05% for 9999 gold) of an XRF Precious Metal Analyzer requires ongoing diligence beyond initial setup and daily calibration. Critical factors include:

Environmental Control: Operate the analyzer within specified temperature ranges (e.g., 10℃~35℃ for desktops, -20℃~50℃ for portables) and ideal humidity (40%-70% non-condensing). Stable conditions prevent component stress and measurement drift.

Stable Power Supply: Always use a regulated power supply or UPS (Uninterruptible Power Supply). Voltage fluctuations can damage sensitive electronic components, directly impacting accuracy and longevity.

Adherence to Protocols: Strictly follow the manufacturer's operation manual, avoiding unauthorized software modifications or private parameter settings.

Detector Protection: Never touch the delicate detector window with fingers or sharp objects, as damage severely impacts accuracy and requires costly repair. These practices ensure consistent, trustworthy results day after day.

Long-term reliability and consistent high performance of your XRF Precious Metal Analyzer depend significantly on regular maintenance:

Daily Exterior Cleaning: Wipe the outer shell with a soft cloth daily to prevent dust and grime buildup.

Test Window Inspection: Before each use, visually inspect and gently clean the test window to ensure no dust or debris interferes with the X-ray path.

Vent & Fan Cleaning: Regularly clean the equipment's fans and ventilation openings to prevent dust accumulation, which can cause overheating and damage internal components.

Environmental Consistency: Continuously maintain the recommended operating temperature and humidity as unstable environments accelerate wear.

Power Management: Always use a voltage stabilizer or UPS to protect the electronics from power surges or instability.

Proper Shutdowns: Avoid forced power-offs or frequent on/off cycles, which stress components and reduce lifespan.

These practices prevent component degradation, maintain optimal operating conditions, and safeguard the precision optical and electronic systems, directly extending the analyzer's lifespan and ensuring its continuous accuracy.

What did our happy clients say?

Our latest acquisition, the VRAY VR-S7 XRF Precious Metal Analyzer, is phenomenal! Its 0.01% accuracy for 9999 gold and SDD detector are top-tier. The 11.6" touchscreen and Win11 system are incredibly smooth for lab work. Highly recommended for ultimate precision.

We've just invested in the VRAY VR-M5 XRF Precious Metal Analyzer. At 4.1Kg, its 0.05% accuracy is impressive. The 5.7" retractable screen and 5MP camera make detailed inspections easy. Excellent for both shop and fieldwork in varied temperatures (-20℃~50℃). Highly satisfied!

My recent acquisition of the VRAY VR-X5 XRF Precious Metal Analyzer has proven superb. Its 0.05% accuracy and K(19)-U(92) elemental range are perfect. The 40s test time and integrated i5 computer make analysis highly efficient for our refinery. A powerful tool!

Having just integrated the VRAY VR-S7 XRF Precious Metal Analyzer, its speed is striking. The 30s test time and powerful 50W beryllium window X-ray tube ensure rapid 0.01% accuracy. The i5 Win11 system handles our complex analyses flawlessly. Absolutely recommend!