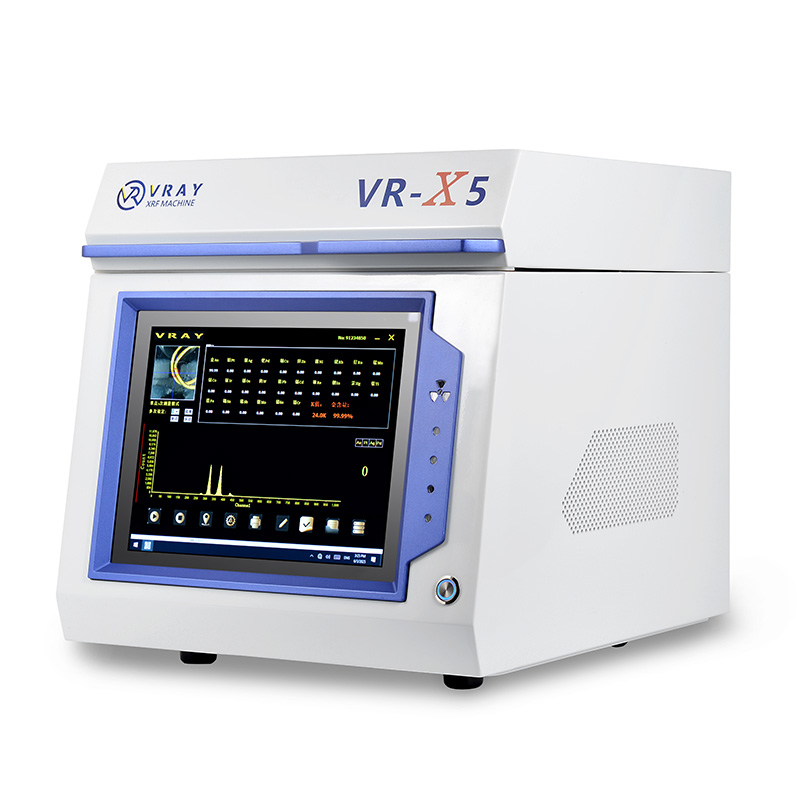

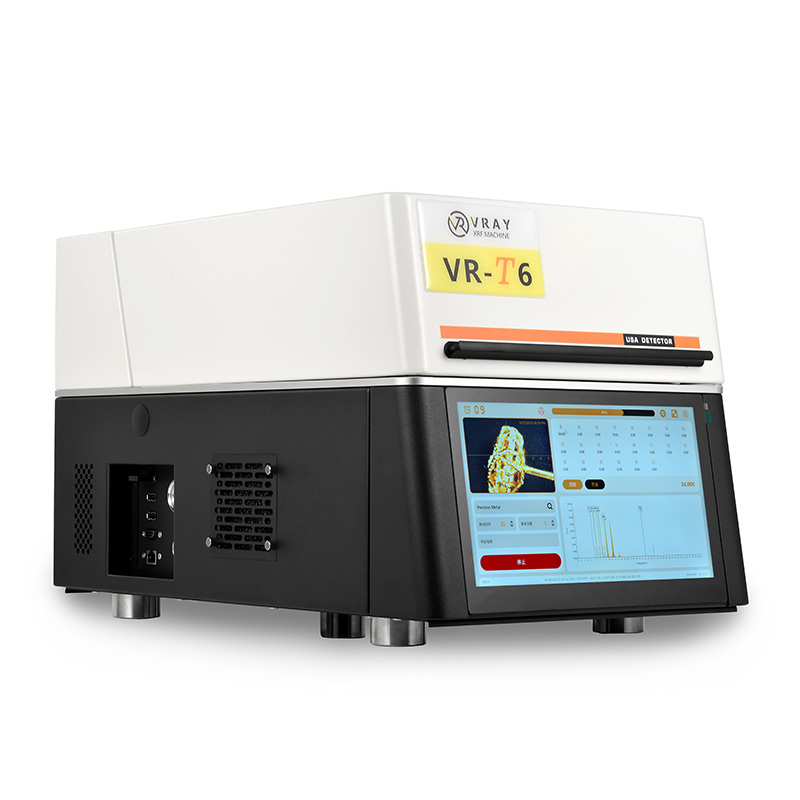

VRAY offers advanced Jewelry X-ray Machine solutions, utilizing state-of-the-art X-ray Fluorescence (XRF) technology for precise and non-destructive precious metal analysis.

Feature | VRAY VR-X5 | VRAY VR-H5 |

Model Type | All-in-one desktop gold tester | All-in-one desktop gold tester, more compact |

Main Function | Specifically designed for gold analysis | Ideal for solid/liquid/powder samples, versatile |

Detection Size | mm | mm |

Chamber Size | mm | mm |

N/G Weight | ||

Test Time | 10s (initial result in 3s) | 40s |

Detector Type | Si-PIN proportional detector | Customized Si-PIN detector |

Test Accuracy | 0.1% for gold | 0.003 for 9999 gold |

Element Range | Au, Ag, Cu, Pt, Pd, Ir, Cd | ALL (F-U) |

X-Ray Tube | PDT (50 KV), full mirror-focused tungsten tube | PDT (50 KV), full mirror-focused tungsten tube |

Collimator | mm | mm |

Safety Protection | Dedicated T-shaped indicator for heat dissipation; no external cooling needed | Dedicated T-shaped indicator for heat dissipation; no external cooling needed |

Built-in Computer | Intel Atom/Indigo highly integrated industrial motherboard | Intel K megate |

Rated Power | ||

Temperature |

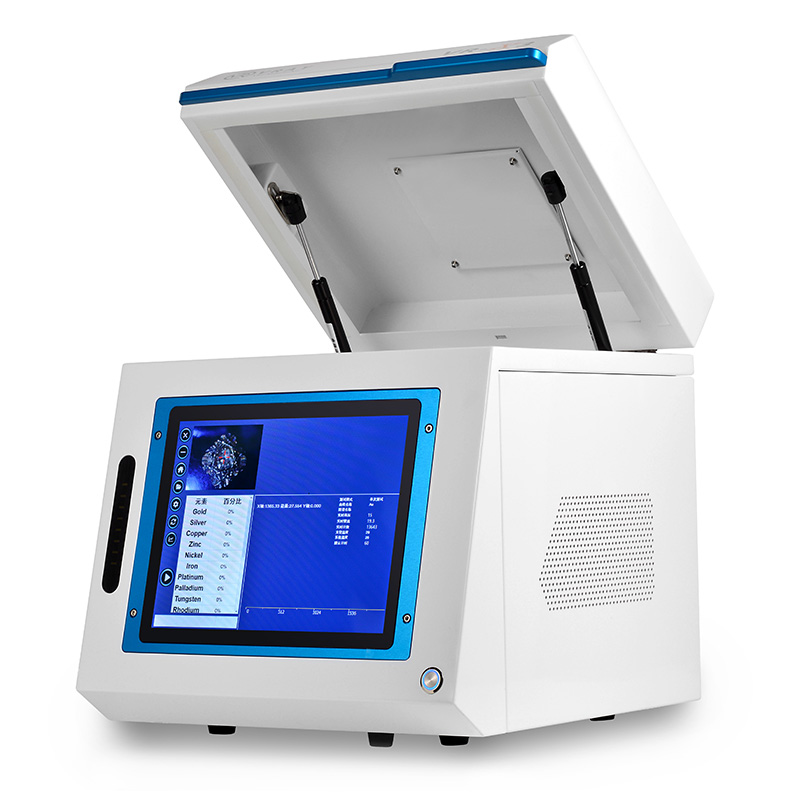

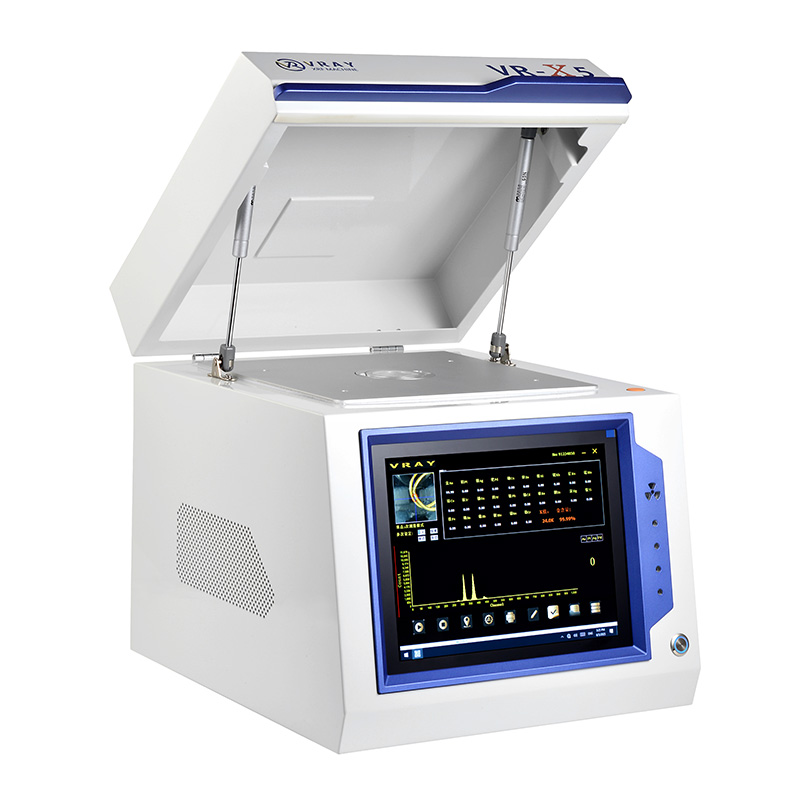

VRAY's jewelry X-ray machines leverage cutting-edge X-ray Fluorescence (XRF) technology, providing rapid, non-destructive analysis of precious metals. Our advanced Si-PIN detectors ensure high accuracy and precision, critical for verifying gold purity and identifying various elements like Au, Ag, Cu, Pt, Pd, Ir, and Cd. The full mirror-focused tungsten X-ray tubes optimize excitation for clear, reliable results. Integrated industrial computers with intuitive interfaces simplify operation, while robust safety features like dedicated heat dissipation and automatic cut-off mechanisms ensure user protection. Remote assistance and software updates are available, highlighting our commitment to continuous support and innovation.

These jewelry testing machines are widely utilized in:

Jewelry Retail Stores: For instant and accurate verification of gold, silver, platinum, and palladium purity when buying from customers, appraising items, or selling new pieces.

Pawn Shops: To quickly and reliably assess the value and authenticity of jewelry offered as collateral or for sale.

Precious Metal Refineries and Recycling Centers: Essential for determining the exact elemental composition of scrap metal, refining batches, and ensuring the purity of finished products.

Assay Offices and Laboratories: For certification, quality control, and providing independent testing services to the industry.

Jewelry Manufacturing Workshops: To monitor material quality during production, ensuring consistency and adherence to purity standards.

Customs and Border Control: For inspecting imported or exported precious metal goods to prevent fraud and ensure compliance.

Antique Dealers: To authenticate the metal composition of vintage and antique jewelry without causing damage.

The primary beneficiaries and users of VRAY Jewelry X-ray Machines include:

Jewelers and Retailers: To build customer trust by offering transparent and accurate metal analysis.

Pawn Brokers: For efficient and reliable valuation of goods, minimizing risk.

Precious Metal Buyers and Sellers: Ensuring fair transactions based on verified purity.

Refiners and Recyclers: Optimizing their processes and maximizing recovery of valuable metals.

Quality Control Managers: In manufacturing, to uphold product standards and minimize material waste.

Appraisers and Gemologists: For comprehensive valuation and authentication services.

Financial Institutions: Dealing with precious metal assets, requiring precise purity verification.

Law Enforcement and Customs Agencies: For combating counterfeiting and smuggling.

VRAY Jewelry X-ray Machines are powerful analytical tools that require careful handling to ensure operator safety and maintain optimal machine performance. Adhering to the following guidelines for safe operation, usage, potential hazard awareness, and proper maintenance is crucial.

Startup and Calibration: After powering on, always follow the requirements to protect and calibrate the instrument, especially after turning it on for the first time every day.

Closed Door Operation: Always remember to start the test with the protective door closed to avoid X-ray leakage.

Stable Power Supply: It is recommended to use a regulated power supply or UPS to avoid damage to the X-ray tube and the motherboard caused by voltage fluctuations.

Environmental Control: Please keep the working environment of the equipment dry, clean, and well-ventilated; avoid high temperature and high humidity.

Operational Protocols: Please follow the operation manual and the manufacturer's testing guidelines. Do not modify the parameter settings privately.

X-ray Leakage: If the test is started when the protective door is not closed tightly, X-rays may leak and cause radiation damage to the operator.

Avoid Forced Shutdown: Frequent, sudden powering off or turning the machine on and off forcefully will easily damage the X-ray tube, high-voltage module, or hard disk, causing the system to crash.

Environmental Impact: In a humid, hot, or dusty environment, the device may overheat, the motherboard may get damp, and the detector may short-circuit.

Software Modifications: Unauthorized modifications of software parameters or calibration data may cause data distortion. In such cases, the software needs to be returned to the factory for recalibration.

Detector Window Protection: Touching the detector window with sharp objects or fingers will damage the detector film (back to the BD protection window), which will result in extremely high maintenance costs.

Pinch Hazard Prevention: During the test, moving the sample or opening the door carelessly can cause the sample to shift, resulting in test failure and potential exposure to X-rays if hands are placed inside.

Radiation Exposure: The primary danger is X-ray radiation. The machine produces radiation during operation, and if the protective door is not closed correctly or the device is damaged, radiation leakage can occur, causing harm to the human body.

Electrical Shock Risk: The equipment contains high-voltage components internally. Unauthorized disassembly or improper operation may lead to electric shock.

Equipment Damage: Improper power supply, harsh operating environments, or violation of operating procedures can lead to damage to the precision components inside the machine, affecting its performance or even rendering it unusable.

Data Distortion: Unauthorized software modifications or changes to calibration data may lead to inaccurate measurement results, thereby affecting the appraisal and valuation of jewelry.

Daily Cleaning: Wipe the outer shell with a clean, soft cloth or lint-free cloth every day to prevent dust accumulation.

Detector Window Inspection: Every few days, check whether there are any foreign objects or contamination on the test window. Keep it clean and transparent.

Regular Vent Cleaning: Regularly clean fans and vents to prevent blockages and ensure proper cooling.

What did our happy clients say?

This VRAY Jewelry X ray Machine (VR-X5) is a game-changer! Its 0.1% gold accuracy and 10s test time are phenomenal. The Si-PIN detector gives reliable, non-destructive results. A compact, robust desktop unit. Highly recommended for jewelers!

Our VRAY Jewelry X ray Machine (VR-H5) offers incredible versatility – handling solids/liquids/powders with ALL(F-U) element analysis and 0.003 accuracy for 9999 gold! Unmatched precision makes it vital for our diverse appraisal work.

The VRAY Jewelry X ray Machine quality is evident. Its built-in industrial computer and T-shaped heat dissipation are excellent. So user-friendly, its XRF technology is consistently accurate. Very confident in this purchase for our lab.

Absolutely thrilled with this VRAY Jewelry X-ray Machine! Its speed and accuracy boost our efficiency. The factory price for such high quality, including a robust PDT 50 KV tube, makes it an unbeatable deal. Best investment for our workshop!