XRF, or X-ray Fluorescence Spectroscopy, is a powerful, non-destructive analytical technique used to accurately determine the elemental composition of materials. By analyzing the unique "fingerprint" of fluorescent X-rays emitted from a sample when excited by a primary X-ray source, XRF allows for both qualitative (identifying elements present) and quantitative (determining element concentrations) analysis. VRAY leverages this sophisticated technology to provide precise and reliable material analysis solutions, from high-value gold testing to critical mineral identification.

The process of X-ray fluorescence involves a series of atomic interactions:

A high-energy primary X-ray beam, typically generated from a controlled X-ray tube (such as VRAY's 50W micro-focused tubes), is directed at the sample. When these primary X-rays interact with the atoms in the material, they possess sufficient energy to eject electrons from their inner orbital shells (like K or L shells). This ejection creates an unstable vacancy within the atom's electron structure.

To regain stability, an electron from a higher energy orbital shell will immediately transition or "jump down" to fill the vacancy in the inner shell. As this electron falls to a lower energy state, it releases the excess energy in the form of a photon of X-ray radiation. This emitted X-ray is known as a fluorescent (or secondary) X-ray. Crucially, the energy of this emitted fluorescent X-ray is unique and characteristic to the specific element from which it originated.

The emitted fluorescent X-rays are then collected by a highly sensitive detector. The detector measures the energy and intensity of each incoming X-ray photon. For instance, VRAY's VR-S7 utilizes a high-sensitivity SDD detector for superior spectral resolution and exceptional 0.01% accuracy for 9999 gold. Models like the VR-T6 and VR-M5 employ customized Si-Pin detectors from the USA to ensure robust performance and high accuracy (e.g., 0.03%-0.05% for 9999 gold). By analyzing the peak energy of these X-rays, the elements present in the sample are identified (qualitative analysis), and the intensity (height) of these peaks is directly proportional to the concentration of each element, enabling precise quantitative analysis.

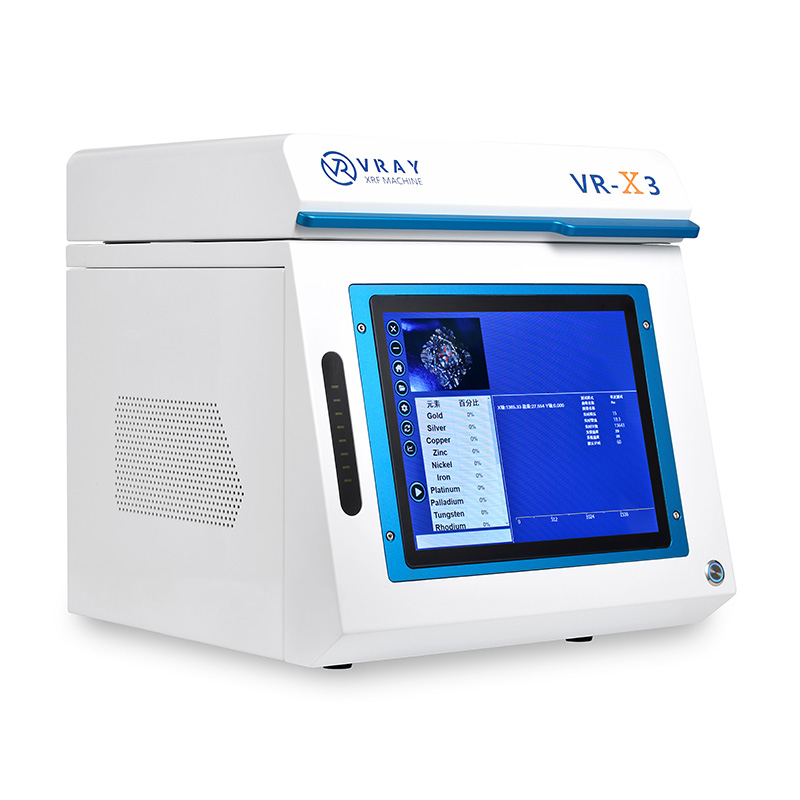

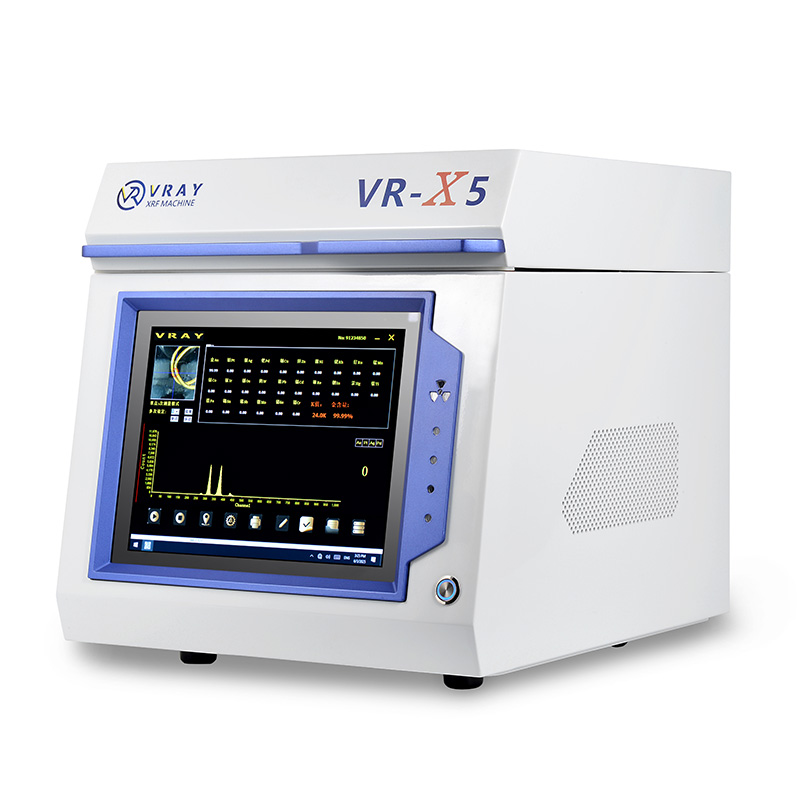

XRF spectrometers primarily come in two types: Energy Dispersive XRF (EDXRF) and Wavelength Dispersive XRF (WDXRF). VRAY's product line, including advanced desktop (VR-S7, VR-T6) and versatile portable (VR-M5) models, predominantly utilizes sophisticated EDXRF technology due to its advantageous combination of speed, portability, and cost-effectiveness, while still achieving exceptional accuracy.

Energy Dispersive XRF (EDXRF): This type, employed in all of VRAY's analyzers, measures the energy of all emitted fluorescent X-rays simultaneously using a semiconductor detector. EDXRF systems are valued for their compact size, versatility in handling various sample types (solids, liquids, powders), and rapid analysis times (e.g., 30 seconds for all VRAY models). VRAY's VR-S7 stands out with its SDD detector for ultimate precision and broad elemental range (K to U), making it ideal for demanding laboratory environments. The VR-T6 and VR-M5 provide reliable, robust performance with Si-Pin detectors, suitable for both daily lab use and challenging on-site applications (e.g., VR-M5's wide -20℃~50℃ operating temperature range).

XRF spectroscopy is characterized by several key features that make it widely applicable across numerous sectors:

Non-destructive: It analyzes materials without altering or damaging the sample, preserving valuable items.

Versatile: Capable of analyzing a wide range of materials including metals, minerals, soils, liquids, and powders.

Rapid Analysis: Provides quick, real-time results, enabling immediate decision-making in fast-paced environments.

Elemental Analysis: Focused on accurately determining the elemental composition.

These features underpin XRF's common applications across diverse industries:

Materials Science & Manufacturing: For rapid quality control, positive material identification (PMI), and composition analysis of alloys, coatings, and various manufactured products.

Geology & Mining: Essential for identifying minerals, assaying ore grades (e.g., gold concentration), and geochemical mapping during exploration and extraction. VRAY's specialized Gold and Mineral Testers excel in these areas.

Environmental Monitoring: Assessing pollution levels, detecting trace amounts of hazardous heavy metals in soil, water, and air for regulatory compliance and remediation efforts.

Precious Metals (e.g., Gold Testing): Accurately determining the purity of gold, silver, platinum, and other precious metals in jewelry, coins, and scrap to prevent fraud, ensure fair trade, and optimize recycling processes.

VRAY's diverse range of desktop and portable Gold Tester Machine and Mineral Analyzer models are designed to meet these varied application needs, offering tailored solutions for every professional requirement.

While XRF analyzers emit X-rays, modern devices are designed with robust safety features like interlocks, shielding, and indicator lights to minimize radiation exposure. Operators are always advised to strictly follow the ALARA (As Low As Reasonably Achievable) principle by minimizing exposure time, maximizing distance from the X-ray beam, and utilizing available shielding. Comprehensive radiation safety training and strict adherence to operating protocols are paramount to ensure safe and responsible operation of any XRF instrument.

Address: 5F, No. 21 building, Phase 2,Lianchuang Science&technology Park, Longgang District. Shenzhen, China