X-ray Fluorescence (XRF) is a non-destructive analytical technique used for elemental analysis. Its principle involves irradiating a sample with high-energy X-rays (or gamma rays), which causes inner-shell electrons within the sample's atoms to be excited and ejected, creating vacancies. As outer-shell electrons fill these vacancies, they emit secondary X-rays, known as fluorescent X-rays. The energy and intensity of these fluorescent X-rays serve as qualitative (what elements are present) and quantitative (how much of each element) signatures for the specific elements in the sample.

Thus, XRF technology enables rapid and accurate identification of elemental composition and their respective concentrations within a sample by detecting and analyzing these characteristic X-rays.

X-ray fluorescence (XRF) is an analytical technique used to determine the elemental composition of materials. It works by exciting atoms within a sample with X-rays, causing them to emit secondary (or fluorescent) X-rays. These emitted X-rays are unique to each element, allowing the XRF analyzer to identify and quantify the elements within the sample.

X-ray Emission

| Fluorescent X-ray Production

| Detection and Analysis

|

XRF technology has diverse applications across numerous industries:

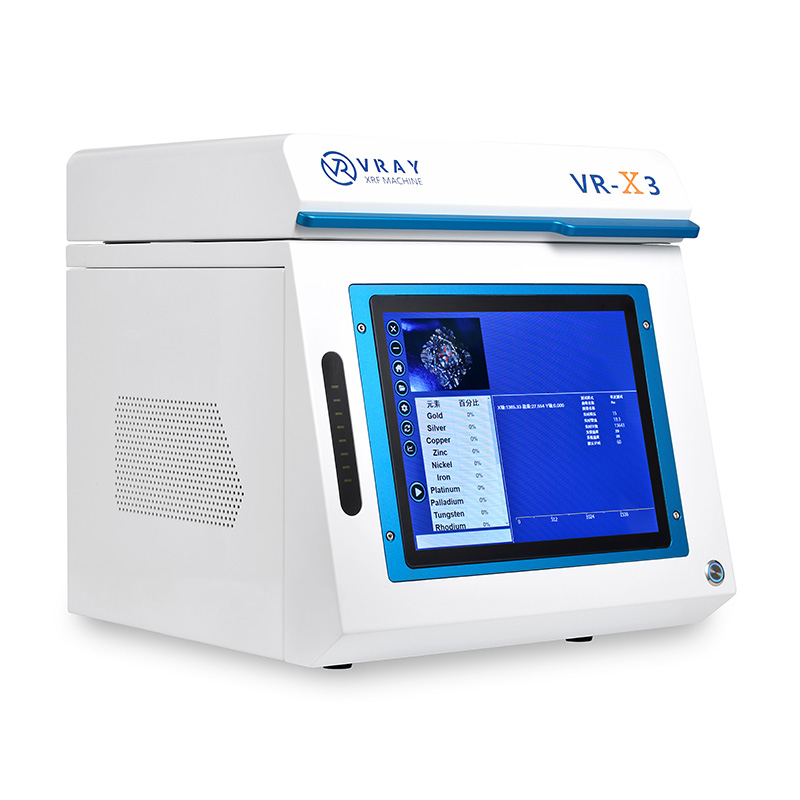

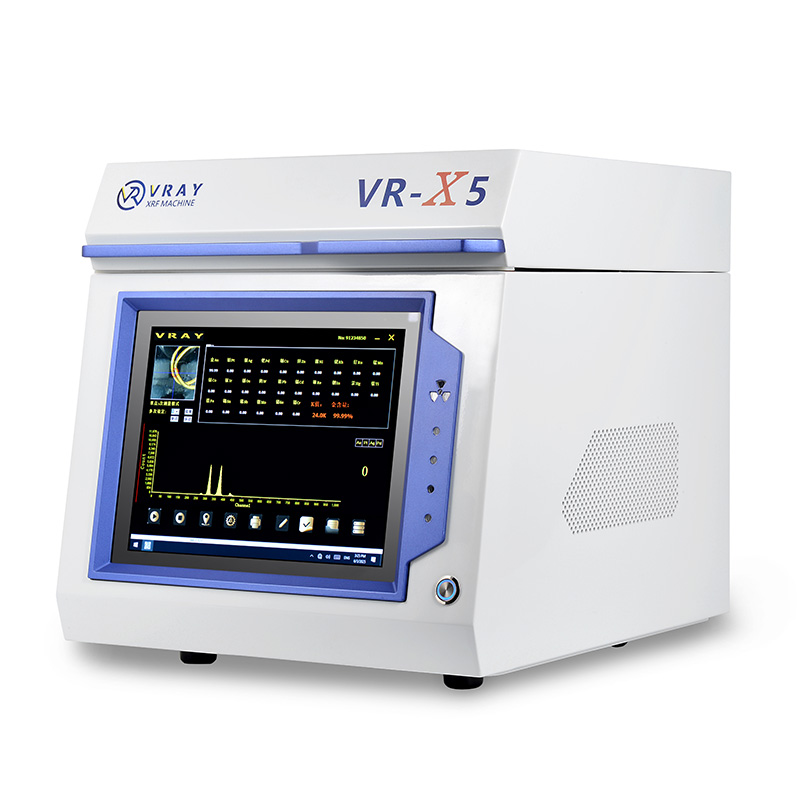

1. Jewelry and Precious Metals

| 2. Mining and Geology

|

XRF is used to sort metals and alloys in recycling facilities, enabling precise sorting that maximizes the value of recyclable materials.

4. Environmental Science

| 5. Manufacturing and Quality Control

|

Here are the advantages of XRF Technology, expanded to include more distinct benefits:

Non-Destructive Testing: A primary advantage, XRF allows for elemental analysis without physically altering or damaging the sample. This preserves the integrity of valuable or irreplaceable materials, such as precious jewelry, artwork, or critical industrial components, making it indispensable where sample preservation is paramount.

Speed and Efficiency: XRF delivers remarkably rapid, near-instantaneous elemental results, often within seconds. This significantly enhances workflow efficiency, enabling quick decision-making and high-throughput analysis in environments like production lines, recycling facilities, or on-site geological surveys.

High Precision and Accuracy: Equipped with advanced detectors and sophisticated algorithms, XRF analyzers provide exceptional precision and accuracy in detecting and quantifying a wide range of elements, from major components to trace levels (down to ppb range). This is crucial for industries with strict regulatory standards, material certification, and complex alloy analysis.

Cost-Effectiveness: The non-destructive nature of XRF testing eliminates sample waste, leading to substantial cost savings, particularly when dealing with high-value materials. It also reduces the need for expensive chemical reagents, complex sample preparation, and associated labor costs, offering a strong return on investment.

Minimal to No Sample Preparation: Unlike many other analytical methods, XRF often requires very little to no sample preparation. Solid, liquid, powdered, or even irregularly shaped samples can frequently be analyzed directly, greatly simplifying the operational process and saving significant time and effort.

Broad Elemental Analysis Range: XRF technology can detect a wide spectrum of elements on the periodic table, typically from Sodium (Na) to Uranium (U). This extensive elemental coverage makes it highly versatile for diverse applications across metallurgy, geology, environmental science, consumer goods, and more.

Portability and On-site Analysis Capability: The development of handheld and portable XRF devices brings laboratory-grade analytical capabilities directly to the field. This allows users to conduct real-time, accurate elemental analysis on-site—whether in the field, on a factory floor, or at a remote location—facilitating immediate decision-making and enhancing operational flexibility.

XRF technology, an advanced non-destructive elemental analysis method, offers significant advantages: speed, precision, cost-effectiveness, and no sample damage. It's crucial in jewelry, mining, recycling, environmental monitoring, and industrial quality control. Its broad elemental range and growing portability ensure vast application prospects. XRF effectively solves material identification and quality control challenges, providing efficient, reliable solutions that drive industrial progress.

Address: 5F, No. 21 building, Phase 2,Lianchuang Science&technology Park, Longgang District. Shenzhen, China