VRAY Production Line: Precision Manufacturing for XRF Analyzers

VRAY's production line is a testament to precision engineering and meticulous quality control, designed to bring our cutting-edge XRF (X-ray Fluorescence) analyzers from concept to reality. We operate a streamlined and comprehensive manufacturing process, ensuring every instrument meets the highest standards of performance and reliability.

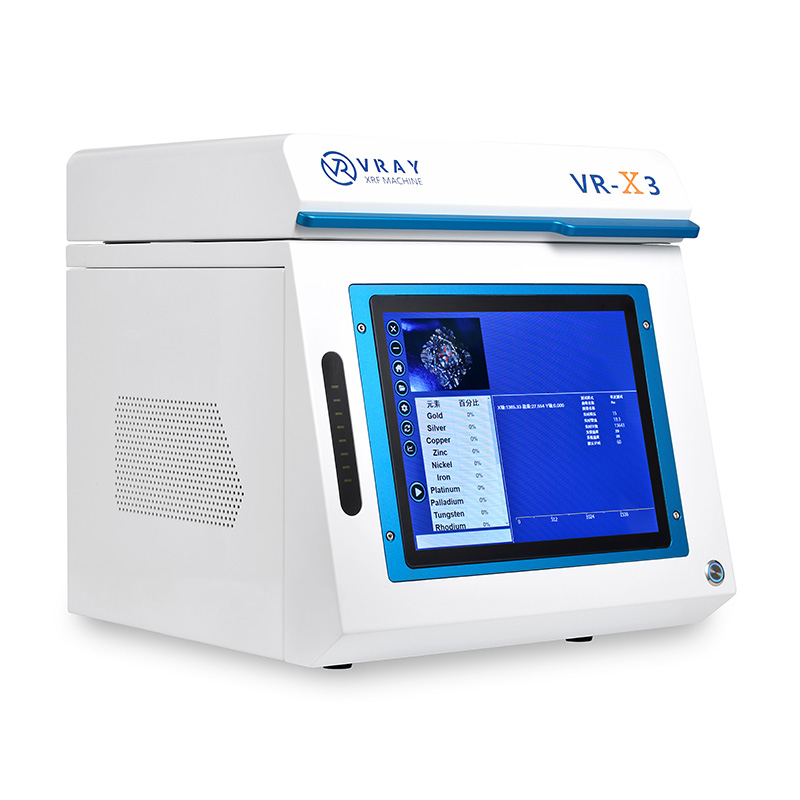

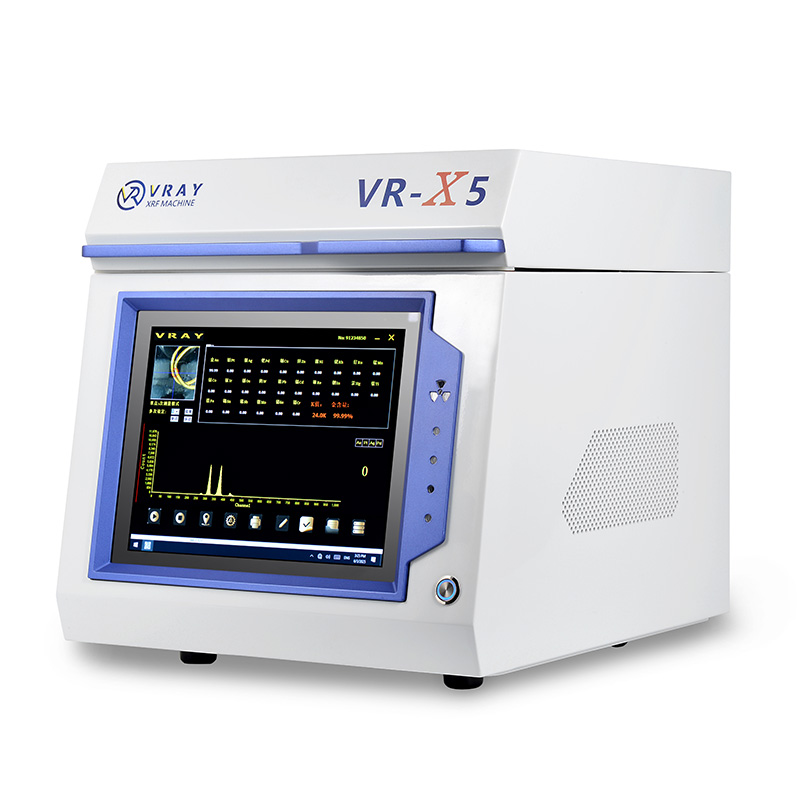

Our Product Lines

At VRAY, our production capabilities encompass a diverse range of XRF analyzer models, each tailored to specific industry needs:

Handheld XRF Analyzers: These portable devices are assembled for rapid, on-site elemental analysis across various applications like alloy identification, environmental screening, and mining exploration. The production line focuses on robust design, ergonomic handling, and consistent analytical performance.

Benchtop XRF Analyzers: Designed for laboratory and industrial environments requiring higher precision and sample throughput, our benchtop units undergo assembly with a focus on advanced optics, sophisticated detection systems, and integrated sample chambers.

Online/Process XRF Analyzers: For continuous, real-time elemental analysis in industrial processes, these complex systems are built to withstand challenging operational conditions, emphasizing durability, automation, and seamless integration into larger production flows.

Comprehensive Production Departments

Our integrated production line is orchestrated by several specialized departments, each playing a critical role in bringing a VRAY XRF analyzer to life:

Component Receiving & Inspection: This initial stage rigorously inspects all incoming raw materials and electronic components, ensuring they meet VRAY's stringent quality specifications before entering the assembly process.

Electronics Assembly & Soldering: Skilled technicians meticulously assemble printed circuit boards (PCBs) and integrate complex electronic modules, performing precise soldering and wiring for the analyzer's intricate internal systems.

Mechanical Assembly: Here, the structural components, including the instrument housing, sample chambers, and X-ray shielding, are precisely assembled. This department ensures the physical integrity and alignment of all mechanical parts.

Optics & Detector Integration: This highly specialized area is responsible for the delicate installation and alignment of the X-ray tube, detector, and optical path components. This stage is critical for the instrument's analytical accuracy.

Calibration & Testing: Once fully assembled, each analyzer undergoes extensive calibration using certified reference materials. Comprehensive functional tests are performed to verify performance, accuracy, and stability across its entire operational range.

Software Loading & Configuration: The proprietary VRAY operating software and application-specific libraries are loaded onto the analyzer. This department also configures settings to meet specific customer requirements or standard applications.

Final Quality Control (FQC): Before packaging, every analyzer undergoes a rigorous final inspection, including visual checks, performance verification, and a comprehensive review of all previous test results, ensuring it meets VRAY's benchmark for excellence.

Packaging & Shipping: The finished instruments are carefully packaged to prevent damage during transit, complete with all necessary accessories and documentation, ready for global distribution.

Through this meticulous and integrated production process, VRAY ensures that every XRF analyzer leaving our facility embodies the precision, reliability, and innovation our customers expect.