VRAY offers a comprehensive range of XRF analyzers designed to meet diverse analytical needs across various industries, from precious metals and jewelry to scrap recycling and geological exploration. Our instruments deliver rapid, non-destructive elemental analysis, providing accurate results for solid, liquid, and powder samples.

Understanding the XRF analyzer price involves looking beyond the sticker price to the advanced technology, precision, and unique features embedded in each model. Our selection spans from highly accessible entry-level options to top-tier, high-precision instruments, with prices ranging from $6,000 to $22,000 USD. This guide provides a detailed breakdown of our pricing, helping you identify the ideal VRAY XRF analyzer that aligns with your specific requirements and budget.

The cost of an XRF analyzer is a composite of its sophisticated hardware components and the intelligent software that drives its performance. At VRAY, we integrate cutting-edge technology to deliver both precision and value.

Detector Technology: This is arguably the most significant hardware cost driver.

High-Sensitivity SDD (Silicon Drift Detector): Found in our higher-end models like the VR-S7 and VR-T7, SDD detectors offer superior energy resolution, allowing for extremely precise identification and quantification of elements, even at trace levels (e.g., 0.01% accuracy for 9999 gold). Their complex manufacturing and performance capabilities contribute significantly to the higher price.

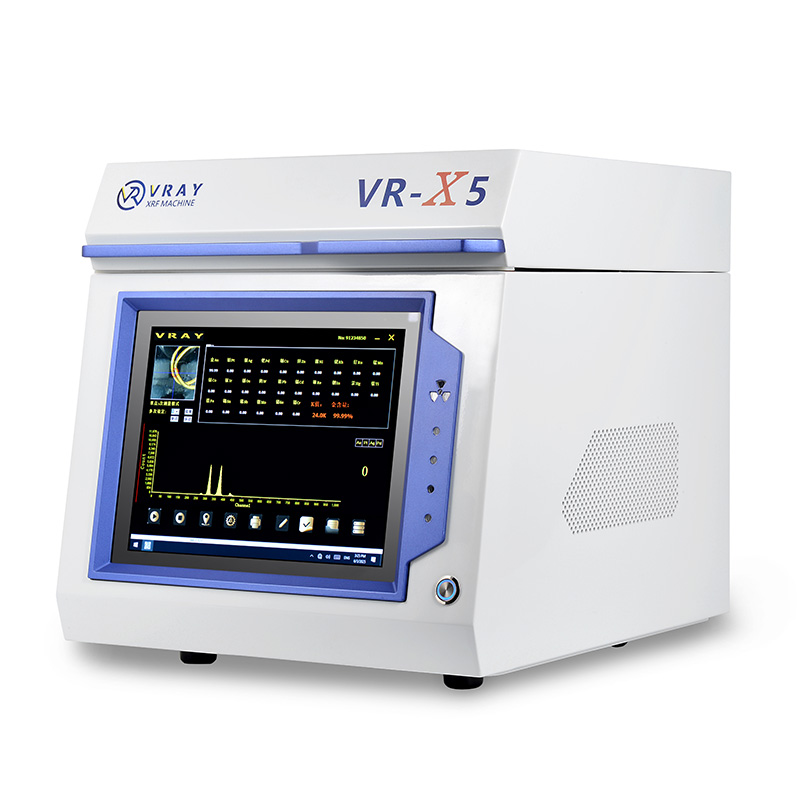

Customized Si-Pin Detector: Utilized in models such as the VR-H5, VR-M5, VR-X5, VR-S6, and VR-T6, Si-Pin detectors provide excellent accuracy (e.g., 0.03% to 0.05% for 9999 gold) at a more cost-effective point. They are robust and reliable for a wide range of gold and precious metal applications.

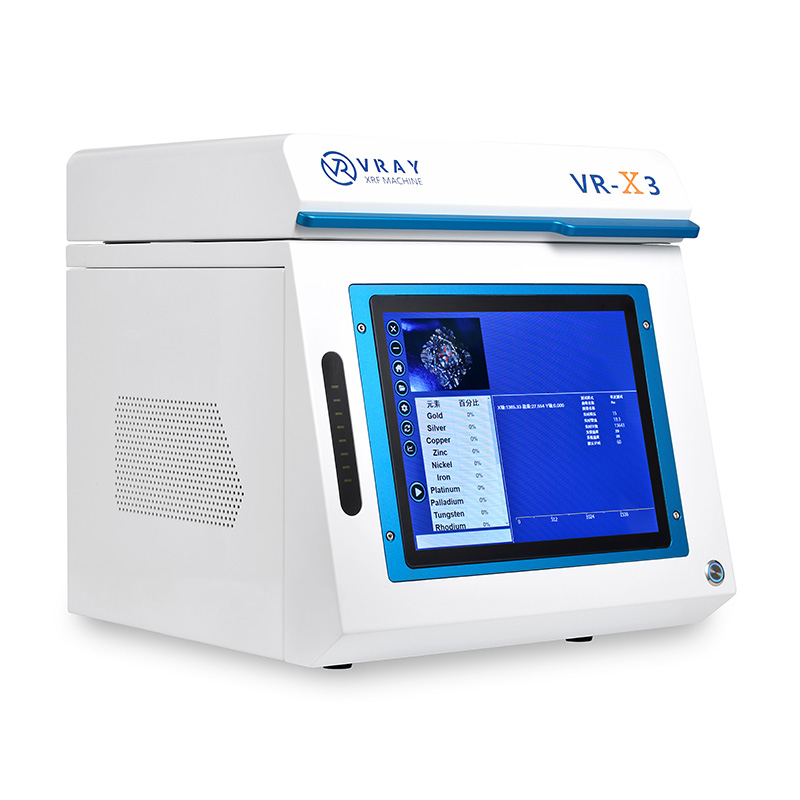

Gas Proportional Counter: The VR-X3 typically uses this detector, which offers basic yet reliable performance for general gold verification at the lowest hardware cost.

X-ray Tube Specifications: The X-ray tube is the excitation source.

All VRAY models feature a 50W micro-focused X-ray tube. However, tubes with specialized windows (e.g., beryllium window on the VR-T7) enable better detection of lighter elements, expanding the analyzer's versatility for broader material analysis, thus increasing its hardware cost.

Mechanical and Optical Components:

Sample Stages: Advanced features like a manual XY sample platform (on the VR-T7) for precise positioning, and larger chamber sizes that accommodate bigger samples, contribute to mechanical complexity and cost.

Cameras and Optics: High-resolution cameras (e.g., 5-megapixel on VR-M5, VR-T7) with significant magnification capabilities (e.g., 40x-160x on VR-T7) for detailed sample viewing and targeting add to the hardware cost.

Form Factor and Material Science:

Portability: Designing handheld (VR-H5) and portable (VR-M5) units requires advanced miniaturization, robust housing materials, and efficient heat dissipation systems, making them more expensive per unit of analytical power compared to fixed desktop models. Their specialized intelligent battery systems also factor into the hardware cost.

Desktop Design: While fixed, desktop units (like VR-S6, VR-T6, VR-S7, VR-T7) often feature more substantial build quality for stability in laboratory environments.

Operating System and User Interface:

Many VRAY models, particularly the desktop units like VR-S6, VR-S7, and VR-T6, integrate an inbuilt industrial computer (e.g., i5-1035G7 with Windows 11) and a dedicated touchscreen interface. The licensing for the operating system and the development of intuitive, robust analytical software are significant software costs.

The specialized algorithms that convert raw X-ray data into precise elemental compositions and karat values are proprietary and represent substantial intellectual property, contributing to the overall price.

Data Processing and Management:

The software's ability to quickly process large datasets, store them in ample memory (e.g., 32GB on VR-H5, VR-M5), and facilitate easy data transmission (USB or Bluetooth) across various devices is a software development cost.

Calibration and Application Specificity:

The development of pre-calibrated methods and application-specific software modes (e.g., dedicated gold testing algorithms, alloy analysis libraries) ensures high accuracy for specific materials, reflecting advanced software engineering.

Safety and Diagnostics:

Software for managing safety protocols (e.g., X-ray tube control, interlocks) and self-diagnostic features contributes to the software's value, ensuring reliable and safe operation.

In essence, the XRF analyzer price from VRAY reflects a holistic investment in cutting-edge hardware components, sophisticated software development, and the precise engineering required to deliver dependable, high-performance analytical solutions for diverse industry needs.

What specific application are you looking to use an XRF analyzer for? you can contact VRAY expert team directly.

Address: 5F, No. 21 building, Phase 2,Lianchuang Science&technology Park, Longgang District. Shenzhen, China