VRAY delivers advanced jewelry testing equipment solutions via cutting-edge X-ray Fluorescence (XRF) technology, offering precise, non-destructive precious metal analysis for diverse professional applications.

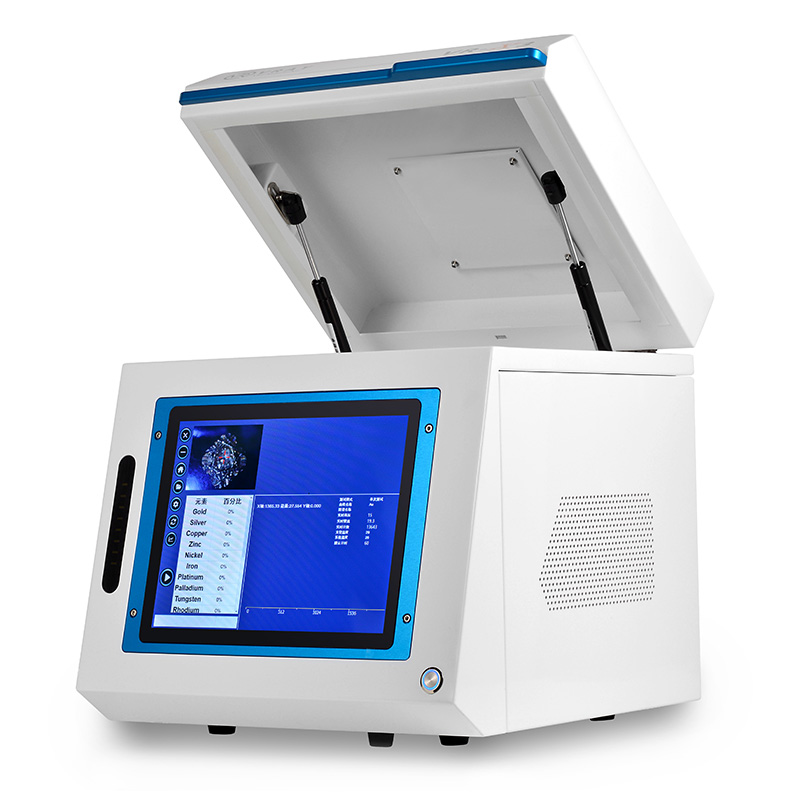

VRAY VR-X3: An easy-to-operate desktop jewelry testing equipment primarily for solids. It features a gas proportional detector, providing 0.1% accuracy for 999 gold (Au, Ag, Cu, Pt, Pd, Ir, Cd). Test time is 50 seconds. (Machine size: 590×555×530mm).

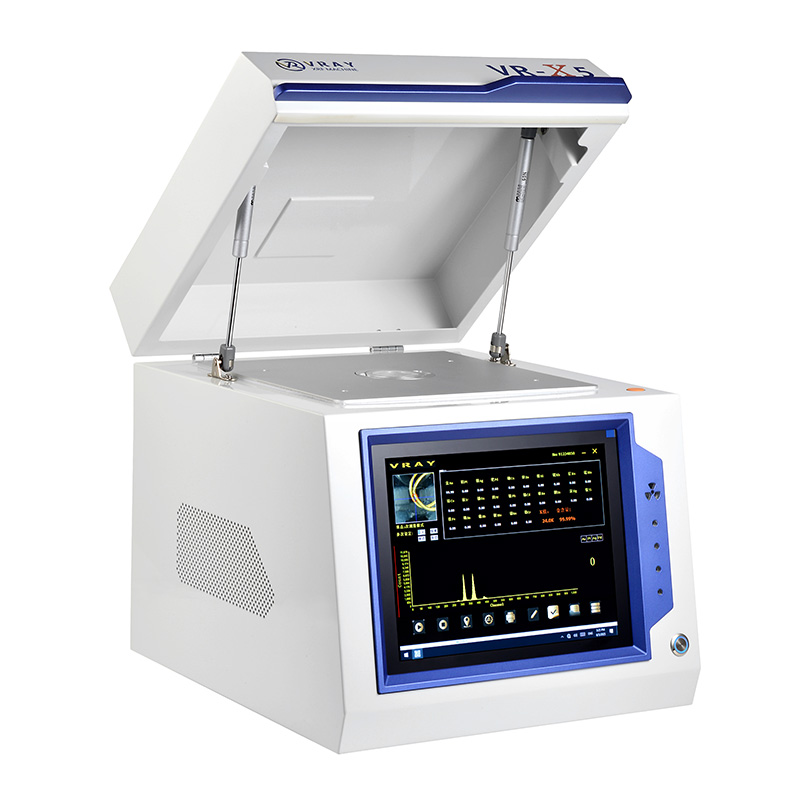

VRAY VR-X5: A high-performance all-in-one desktop jewelry testing equipment. Equipped with a customized Si-Pin detector, it ensures 0.05% accuracy for 9999 gold across a broad elemental range from K(19) to U(92). This versatile model tests solids, liquids, and powders, completing analysis in 40 seconds. (Machine size: 520×450×400mm).

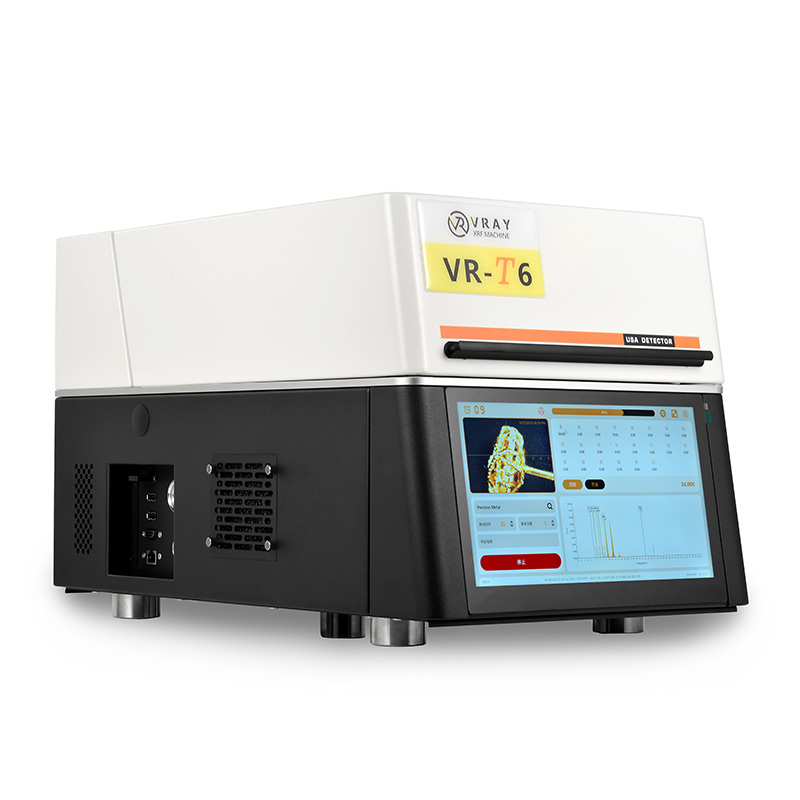

VRAY VR-T6: Our best desktop jewelry testing equipment, offering unparalleled precision. It boasts a USA-sourced customized Si-Pin detector, delivering 0.03% accuracy for 9999 gold. This model performs rapid 30-second tests on solids, liquids, and powders, featuring an i5-1035G7 Windows 11 computer with an 11.6" touchscreen. (Machine size: 330×580×360mm).

All VRAY jewelry testing equipment models uniformly utilize a powerful 50W (50 kV, 1mA) micro-focused tungsten X-ray tube and a ϕ2.5mm collimator for optimal analysis. Core technical solutions include these advanced Si-Pin detectors and integrated safety features like dedicated T-shaped radiators, ensuring efficient heat dissipation without the need for external cooling. Our solutions guarantee rapid, reliable, and highly accurate results for professional precious metal valuation and verification.

A VRAY Jewelry Testing Equipment integrates sophisticated hardware and software. Key hardware includes a 50W micro-focused tungsten X-ray tube that generates the primary X-ray beam, and a ϕ2.5mm collimator to precisely direct it. Advanced detectors, such as gas proportional (in VR-X3) or customized Si-Pin (in VR-X5 and USA-sourced in VR-T6), capture the fluorescent X-rays. An integrated industrial computer (e.g., Intel i5, often with Windows 11 and touchscreen) processes all data, with dedicated T-shaped radiators ensuring safety and efficient heat dissipation.

The jewelry testing equipment operates on the X-ray Fluorescence (XRF) principle. First, the X-ray tube excites the jewelry sample. Atoms within the sample absorb this energy and then emit characteristic secondary X-rays, unique to each element. The detector precisely measures the energy and intensity of these emitted X-rays. The powerful onboard software then analyzes this data, identifying the elements present and accurately quantifying their concentrations. This entire process is non-destructive, providing rapid and reliable elemental composition and purity results directly on the screen, crucial for accurate precious metal valuation.

Model | Type & Primary Function | Price Range (USD) |

VRAY VR-X3 | Easy to operate Desktop Gold Tester | $6,000 - $7,000 |

VRAY VR-X5 | High Performance All-in-one Desktop Gold Tester | $10,000 - $11,000 |

VRAY VR-T6 | Best Desktop Gold Tester | $12,000 - $13,000 |

5 Key Considerations When Purchasing a Jewelry Testing Machine

Testing Accuracy & Performance: Ensure exceptional testing accuracy (e.g., 0.03% for 9999 gold) and stable performance for business reliability.

Test Range & Efficiency: Evaluate its capability for comprehensive testing of solids, liquids, powders, and desired elements, along with test speed.

Equipment Durability & Safety: Examine the machine's robust construction and safety features (e.g., heat dissipation system) for long-term stable operation.

Software Functionality & Operation: Understand if the software is powerful and user-friendly; built-in PC/touchscreen enhance operational convenience.

Comprehensive After-Sales Service: Confirm provision of installation guidance, software updates, technical training, hardware warranty, and remote/on-site support.

VRAY Jewelry Testing Equipments are indispensable tools across various sectors of the jewelry industry, providing precise and non-destructive analysis for:

Precious Metal Purity Testing: Accurately determine the exact karat and fineness of gold, silver, platinum, palladium, and other precious metals.

Jewelry Appraisal and Valuation: Provide reliable data for valuing new, antique, or second-hand jewelry pieces based on their true metal composition.

Quality Control: Ensure the consistency and quality of materials used in jewelry manufacturing and production processes.

Fraud Prevention: Effectively identify counterfeit items, under-karated gold, or misleadingly marked precious metals, protecting businesses and consumers.

Scrap and Recycling Analysis: Quickly analyze the elemental composition of scrap jewelry and precious metal waste for efficient recycling and recovery.

Retail Jewelry Stores: Enhance customer trust by offering on-the-spot verification of jewelry authenticity and purity.

Pawn Shops: Facilitate quick and accurate assessment of collateral value for loans.

Refineries: Aid in the precise sorting and processing of precious metal alloys.

Customs and Border Control: Assist in verifying declared metal content for imported and exported goods.

Ensuring the longevity and accurate performance of your Jewelry Testing Machine relies on diligent operational practices and a clear understanding of emergency protocols. VRAY provides comprehensive guidance for both.

Operational Guidelines for Your Jewelry Testing Machine

Adhering to these guidelines is crucial for safe, accurate, and prolonged operation:

Daily Startup Routine: Always preheat and calibrate the instrument meticulously upon its first use each day.

Safety First: Absolutely ensure the protective door is fully closed before initiating any test to prevent X-ray leakage and ensure operator safety.

Stable Power Supply: Utilize a regulated power supply or Uninterruptible Power Supply (UPS) to shield the Jewelry Testing Machine from voltage fluctuations, which can damage sensitive components.

Environmental Control: Maintain a dry, clean, and well-ventilated working environment. Avoid high temperatures (keep between 15-30°C) and high humidity (below 70%) to protect internal electronics.

Follow Protocols: Strictly adhere to the operation manual and manufacturer's training guidelines. Never modify parameter settings without authorization.

Routine Cleaning: Wipe the machine's outer shell daily with a soft, lint-free cloth to prevent dust accumulation.

Test Window Care: Before each use, inspect the test window for foreign objects or contamination and ensure it remains clean and transparent.

Ventilation Maintenance: Regularly clean fans and vents to prevent blockages that could lead to overheating.

Avoid Over-stress: Refrain from prolonged continuous high-load use. Allow the machine to cool down regularly and avoid frequent forced power-offs or turning the machine on/off abruptly, which can damage vital components like the X-ray tube or hard disk.

Detector Protection: Never touch the detector window with sharp objects or fingers, as this can cause costly damage to the detector film.

VRAY provides prompt solutions for issues that may arise, minimizing downtime for your Jewelry Testing Machine:

Software becomes unusable, or issues occur during updates/upgrades.

Unauthorized software/calibration data modification can lead to data distortion.

Damage to the X-ray tube, detector failure, abnormal high-voltage power module, or protective door sensor malfunction.

X-ray leakage due to testing with an unclosed protective door, posing radiation risk.

Damage to X-ray tube, high-voltage module, or hard disk from frequent forced power cycles.

Overheating or component malfunction (e.g., motherboard dampness, detector short-circuit) in humid, hot, or dusty environments.

Test failure and potential X-ray exposure if samples are moved or the door is opened during a test.

VRAY engineers are available to provide immediate remote support at any time, diagnosing and resolving software-related issues swiftly to restore your Jewelry Testing Machine's functionality.

Option 1 (Parts Mail & Video Guidance): For specific hardware component failures, VRAY can promptly mail necessary accessories. This is complemented by detailed video tutorials and remote guidance from engineers, enabling customers to perform component replacements with ease and speed.

Option 2 (On-Site Engineer Dispatch): For complex hardware failures that require expert physical intervention, VRAY is prepared to dispatch highly skilled engineers directly to your site to diagnose and resolve the problem, ensuring comprehensive repair and minimal operational disruption for your Jewelry Testing Machine.

What did our happy clients say?

We recently acquired the VRAY VR-T6 Jewelry Testing Equipment, and it's phenomenal! Its 0.03% accuracy for 9999 gold and 30s test time are top-notch. The USA-sourced Si-Pin detector and 11.6" touchscreen have greatly enhanced our lab's precision and usability. Absolutely essential.

Having recently installed our VR-X5 Jewelry Testing Equipment, we're impressed! It delivers 0.05% accuracy for 9999 gold, testing K(19)~U(92) elements in just 40s across all sample types. The customized Si-Pin detector ensures consistent, reliable results. A versatile powerhouse for our shop.

We just started using the VRAY VR-X3 Jewelry Testing Equipment for gold analysis, and it's excellent. Its 0.1% accuracy for 999 gold (Au, Ag, Cu, Pt, Pd, Ir, Cd) in 50s is perfect for our needs. The gas proportional detector is precise, and it's incredibly easy to operate. Great value.

Our recent purchase of a VRAY Jewelry Testing Equipment (with its 50W micro-focused X-ray tube and T-shaped radiator for safety) has already proven its unmatched reliability. The non-destructive testing provides critical data, preventing fraud and ensuring strong ROI. A truly superior investment.