Product Details

| Place of Origin: | Jewelry Tester Manufacturer |

|---|---|

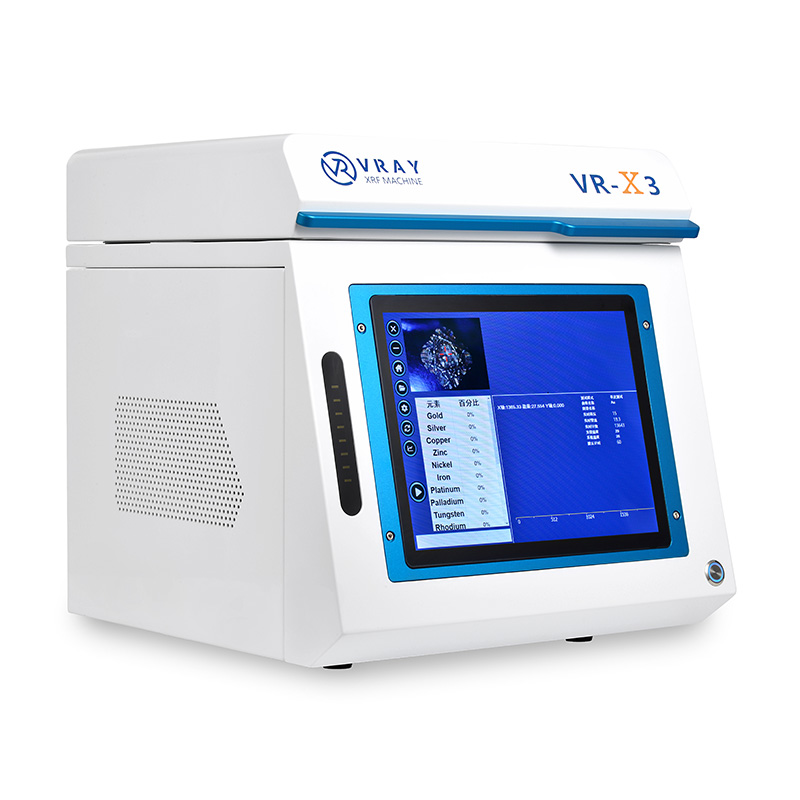

| Brand Name: | VRAY |

| Certification: | ISO CE GOST |

| Model Number: | VR-X3 |

Payment & Shipping Terms

| Min Order: | 1 Set |

|---|---|

| Price: | 6000$-7000$ |

| Packaging: | Strong Case |

| Delivery Time: | 7 days |

| Payment Terms: | TT |

| Supply Ability: | 500 units per month |

Detailed Product Description

Non-Destructive Jewelry Testing Equipment refers to specialized devices, typically X-ray Fluorescence (XRF) analyzers, that determine the precise elemental composition and purity of gold, silver, platinum, and other precious metals in jewelry without causing any damage to the item. Unlike traditional acid tests that can leave marks or even damage delicate pieces, this equipment preserves the integrity and value of the jewelry. Its core function is to provide accurate and reliable analysis for jewelry checking while ensuring the item remains intact.

Model | VR-X3 |

Type | Non-Destructive Jewelry Testing Equipment |

Price | 6000$-7000$ |

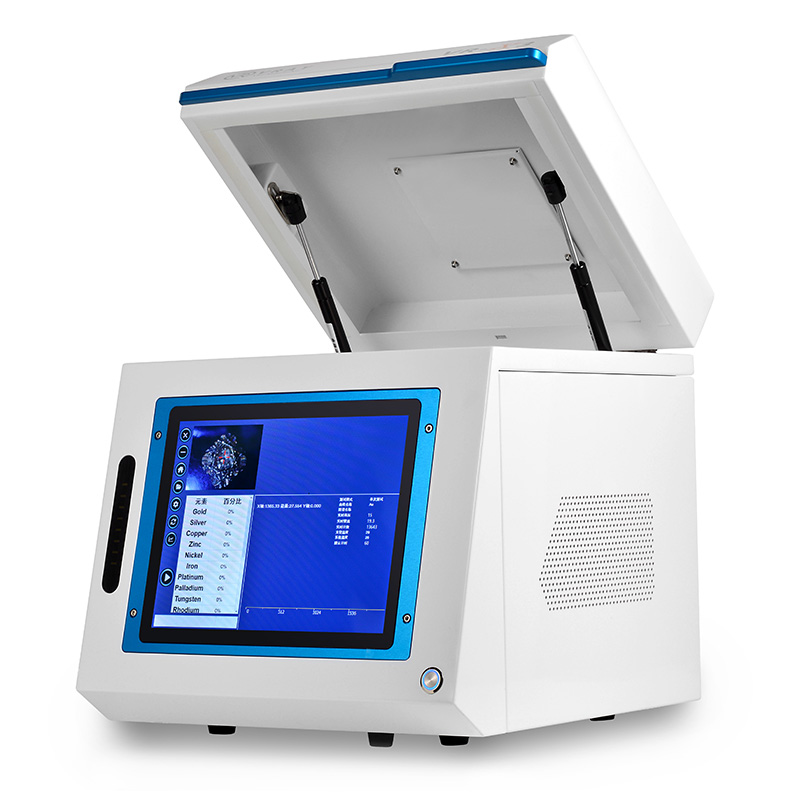

Machine size | 590 x 555 x 530mm |

Chamber size | 320 x 260 x 110mm |

N/G Weight | 33Kg/45KG |

Test time | 50s |

Test range | Solids |

Detector type | Gas proportional detector |

Test accuracy | 0.1% for 999 gold |

Element range | Au, Ag, Cu, Pt, Pd,Ir ,Cd |

X-ray tube | 50W (50 kV, 1mA) micro-focused tungsten ray tube |

Collimator | ϕ2.5mm |

Safety protection | Equipped with a dedicated T-shaped radiator to dissipate the heat; no need to wait for cooling of |

The VRAY VR-X3 Non-Destructive Jewelry Testing Equipment is an all-in-one desktop gold tester meticulously engineered to provide accurate and reliable precious metal analysis while fully preserving the integrity of your valuable jewelry.

This Non-Destructive Jewelry Testing Equipment features a Gas proportional detector and a powerful 50W micro-focused tungsten X-ray tube with a ϕ2.5mm collimator. It delivers a solid 0.1% accuracy for 999 gold and identifies a crucial set of elements: Au, Ag, Cu, Pt, Pd, Ir, Cd. With a test time of 50 seconds and the ability to analyze only solids, it's perfectly suited for typical gold and silver jewelry items and scrap. Despite its affordable price point ($6,000-$7,000), it offers a practical machine size (590 x 555 x 530mm) and a generous chamber size (320 x 260 x 110mm) to accommodate various jewelry pieces comfortably. Its robust build (33Kg N/G Weight) ensures stability for daily use. Equipped with a dedicated T-shaped radiator, it operates continuously without cooling delays, ideal for consistent workflow where non-destructive testing is paramount.

The VRAY VR-X3 Non-Destructive Jewelry Testing Equipment is designed with key features that emphasize its core capability: non-destructive analysis coupled with reliability.

Truly Non-Destructive Analysis: Utilizes X-ray Fluorescence (XRF) technology to analyze precious metals without requiring any cutting, scratching, or acid application, completely preserving the integrity and value of the jewelry. This is the defining feature of Non-Destructive Jewelry Testing Equipment.

Reliable Accuracy: Provides 0.1% accuracy for 999 gold, offering a solid and dependable foundation for purity verification essential for appraisals and purchasing decisions.

Fast Test Time: Delivers results in just 50 seconds, allowing for quick assessment of items, which speeds up customer interactions and operational efficiency.

Targeted Elemental Detection: Specifically designed to detect essential elements found in jewelry and precious metals: Au (Gold), Ag (Silver), Cu (Copper), Pt (Platinum), Pd (Palladium), Ir (Iridium), and Cd (Cadmium).

Gas Proportional Detector: Features a Gas proportional detector for dependable performance in elemental analysis, providing accurate readings for common jewelry alloys.

Optimized for Solids: Primarily designed for analyzing solid gold and silver jewelry pieces, coins, and scrap items, which represent the majority of jewelry testing needs.

Powerful X-ray Tube: Equipped with a 50W (50 kV, 1mA) micro-focused tungsten X-ray tube with a ϕ2.5mm collimator, ensuring stable and effective X-ray generation.

Compact Desktop Design: As an all-in-one desktop gold tester, it has a practical machine size (590 x 555 x 530mm) and a generous 320 x 260 x 110mm chamber to accommodate various items.

Continuous Operation: Features a dedicated T-shaped radiator for efficient heat dissipation, allowing for uninterrupted use without needing to wait for cooling, ideal for busy work environments.

The Non-Destructive Jewelry Testing Equipment (VRAY VR-X3) addresses several critical challenges for jewelry professionals:

Eliminates Damage to Valuables: It solves the problem of traditional testing methods (like acid tests) that can damage or devalue precious jewelry. With its non-destructive XRF technology, items remain pristine.

Prevents Fraud: Provides accurate and reliable purity percentages, effectively identifying fake or misrepresented gold and silver, protecting businesses from costly mistakes.

Builds Customer Trust: Allows for transparent, on-the-spot testing in front of the customer, fostering confidence and enhancing the buying/selling experience as items are visibly unharmed.

Streamlines Appraisal Processes: Replaces slower, more laborious testing methods with a rapid, accurate solution, significantly speeding up valuation and purchasing decisions.

Reduces Material Loss: Because it's non-destructive, there's no material lost during testing, which is particularly important for high-value items or large quantities of precious metal scrap.

Simplifies Operations: Its desktop, all-in-one design and straightforward operation make professional-grade testing accessible even without specialized laboratory training.

The VRAY VR-X3 Non-Destructive Jewelry Testing Equipment offers distinct advantages for businesses seeking an efficient and reliable method for jewelry checking:

Preservation of Value: The paramount advantage is its non-destructive nature, ensuring that valuable jewelry, antique pieces, or delicate items are never harmed during testing, maintaining their aesthetic and monetary value.

Accuracy & Reliability: Provides 0.1% accuracy for 999 gold, which is highly sufficient for typical jewelry and gold buying applications, ensuring trustworthy results.

Speed & Efficiency: A 50-second test time allows for rapid assessment, leading to quicker customer interactions and higher throughput in busy environments.

Cost-Effective: Priced between $6,000-$7,000, it offers professional XRF capabilities at an accessible price point, making it a smart investment for businesses looking to upgrade from traditional methods.

Safety: Eliminates the use of hazardous chemicals found in acid tests, creating a safer working environment. The machine itself includes safety protection features.

Ease of Use: As an all-in-one desktop unit, it's generally straightforward to operate, minimizing the learning curve for new users.

Comprehensive Elemental Identification: Identifies a relevant range of elements (Au, Ag, Cu, Pt, Pd, Ir, Cd) critical for accurate appraisal of common jewelry alloys.

Purchasing the VRAY VR-X3 Non-Destructive Jewelry Testing Equipment is a straightforward process to equip your business with reliable precious metal analysis:

Assess Your Needs: Confirm that the VR-X3's specifications, particularly its non-destructive capability, 0.1% accuracy for 999 gold, and 50-second test time, align with your specific jewelry testing requirements.

Contact VRAY or an Authorized Dealer: Reach out directly to VRAY or a trusted local distributor. They can provide detailed information, answer technical questions, and offer tailored guidance.

Request a Quote: Obtain a formal price quotation, which will confirm the cost within the $6,000-$7,000 range, along with any shipping fees, taxes, or additional services.

Inquire About Warranty and Support: Discuss the warranty period, available technical support, and any training or maintenance resources provided to ensure long-term reliability of your Non-Destructive Jewelry Testing Equipment.

Review Terms and Conditions: Carefully read the sales agreement, delivery schedule, and payment terms before finalizing your decision.

Place Your Order: Once satisfied, proceed with the purchase. You will typically receive an order confirmation and details regarding shipping and estimated delivery.

The VRAY VR-X3 Non-Destructive Jewelry Testing Equipment is priced competitively between $6,000-$7,000. This investment offers a significant Return on Investment (ROI) for any business dealing with precious metals:

ROI for Non-Destructive Jewelry Testing Equipment:

Direct Prevention of Financial Loss: The most immediate ROI comes from preventing losses due to inaccurate appraisals or purchasing fraudulent gold/silver. The 0.1% accuracy for 999 gold quickly recoups the machine's cost by ensuring precise valuations.

Increased Customer Confidence & Sales: The ability to perform transparent, non-destructive tests in front of customers builds trust, encourages repeat business, and can directly lead to higher sales volumes for jewelry and precious metals.

Reduced Operational Costs: Eliminates the ongoing expense of consumables for traditional acid tests and the potential costs associated with damaging valuable items. It also negates the need for costly third-party assay services.

Improved Efficiency: The 50-second test time allows businesses to process more items per day, directly increasing transaction volume and overall productivity.

Enhanced Professionalism: Owning advanced Non-Destructive Jewelry Testing Equipment elevates your business's image, positioning you as a modern and trustworthy entity in the market.

Preservation of Asset Value: For businesses holding valuable inventory or receiving delicate items, the non-destructive nature ensures no value is lost through testing, maintaining the integrity of high-value assets.

The VRAY VR-X3 is considered Non-Destructive Jewelry Testing Equipment because it uses X-ray Fluorescence (XRF) technology to analyze precious metals. This method provides precise elemental composition without requiring any cutting, scratching, or applying chemicals like acids, thus preserving the original condition and value of your jewelry.

This Non-Destructive Jewelry Testing Equipment offers reliable accuracy, achieving 0.1% for 999 gold. This precision is highly sufficient for jewelry checking, enabling businesses to confidently verify gold purity, identify alloys, and prevent costly misidentifications without damaging the item.

This Non-Destructive Jewelry Testing Equipment provides rapid analysis in just 50 seconds. This fast test time is a significant advantage, allowing for efficient customer interactions and high-volume jewelry checking without causing any harm to the item.

This Non-Destructive Jewelry Testing Equipment is designed to identify a range of common elements found in jewelry. Its element range includes Au (Gold), Ag (Silver), Cu (Copper), Pt (Platinum), Pd (Palladium), Ir (Iridium), and Cd (Cadmium), providing comprehensive non-destructive analysis of typical jewelry alloys.

This Non-Destructive Jewelry Testing Equipment is primarily designed to analyze solids, making it ideal for the vast majority of gold and silver jewelry pieces, coins, and other solid precious metal items. Its non-destructive nature means it's safe for even delicate or antique jewelry.

The VRAY VR-X3 Non-Destructive Jewelry Testing Equipment is priced between $6,000-$7,000. This makes it an accessible and cost-effective investment for businesses seeking to upgrade to a reliable, non-destructive method for jewelry checking, preventing fraud, and enhancing customer trust.