VRAY, with 17 years of manufacturing expertise, delivers advanced Jewelry Checking Machine solutions. Our XRF analyzers provide precise, non-destructive analysis of precious metals, embodying cutting-edge features for reliable results.

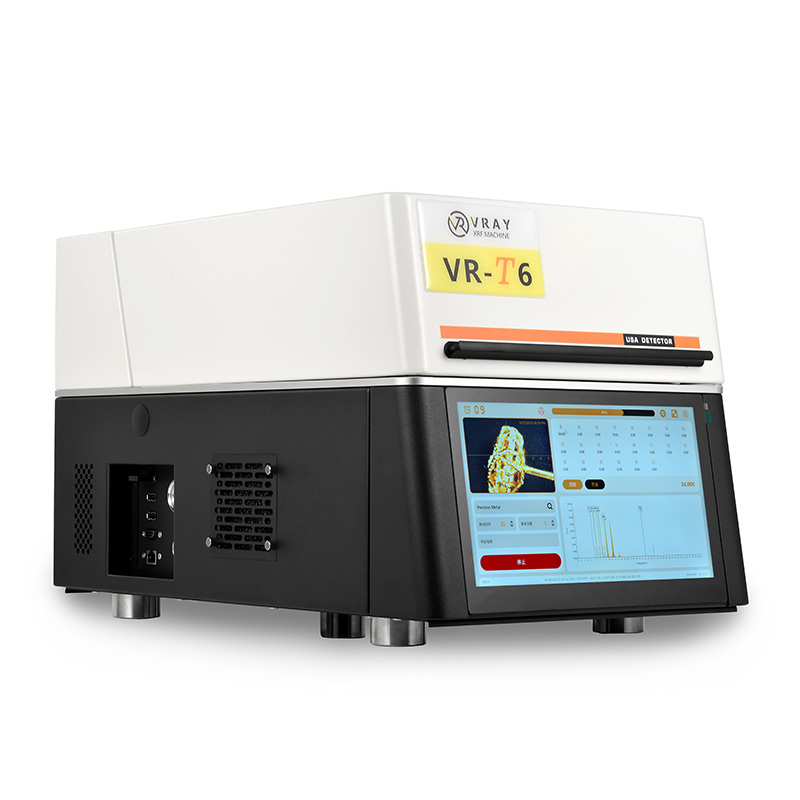

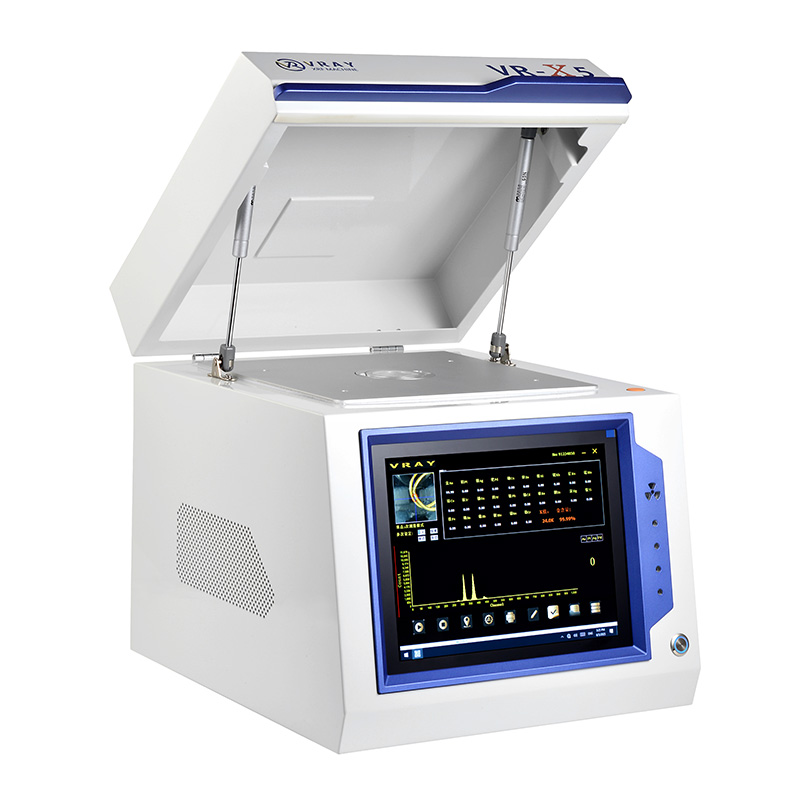

VR-X5 (Desktop): Gold-focused, offers 0.1% accuracy for Au, Ag, Cu, Pt, Pd, Ir, Cd in just 10 seconds, featuring a Si-PIN detector.

VR-H5 (Handheld): Highly versatile for solid, liquid, or powder samples, providing 0.003 accuracy for 9999 gold across ALL(F-U) elements, utilizing a customized Si-PIN detector.

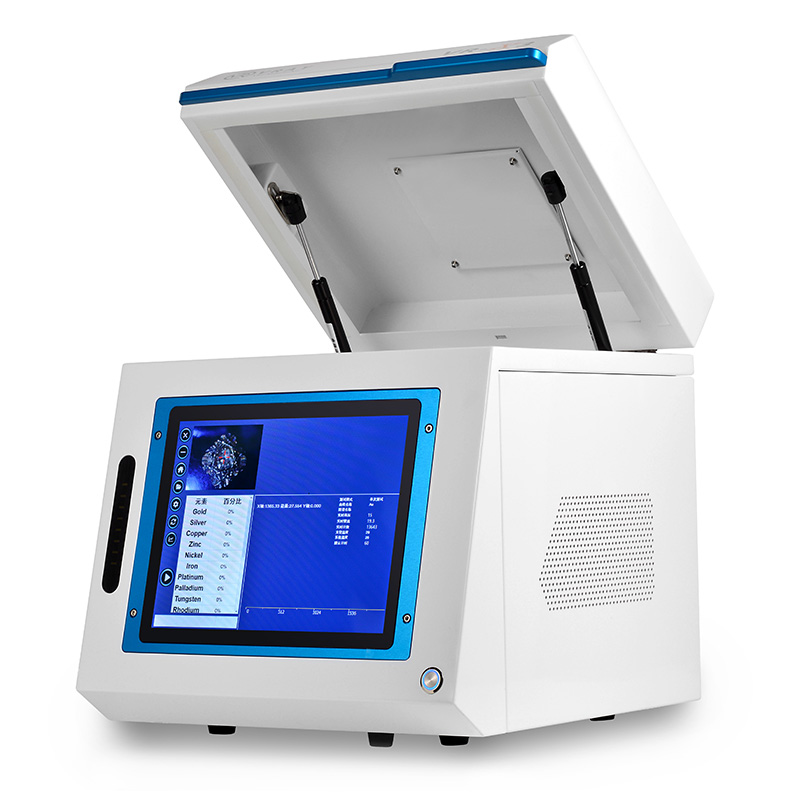

VR-S7 (Benchtop): A portable gold tester, delivering 0.003 accuracy for 9999 gold (Au, Ag, Cu, Pt, Pd, Ir, Cd, Rh) in 20 seconds, equipped with a US-sourced customized Si-PIN detector.

Our core technology features cutting-edge X-ray Fluorescence (XRF), advanced Si-PIN detectors, and robust PDT 50 KV full mirror-focused tungsten X-ray tubes, ensuring superior accuracy, speed, and reliability. Built-in industrial computers and robust safety mechanisms, like dedicated heat dissipation, enhance usability and operator protection.

Key advantages of a VRAY Jewelry Checking Machine include rapid, non-destructive material analysis, which prevents costly misidentifications and significantly boosts customer confidence. Priced competitively, our solutions offer a substantial Return on Investment (ROI) by optimizing valuation processes and enhancing operational efficiency for any jewelry professional. Choose VRAY for trusted, high-performance jewelry analysis.

Model | Type & Primary Function | Price Range (USD) |

VRAY VR-X5 | Desktop Jewelry Tester | $7,000 - $8,000 |

VRAY VR-H5 | Handheld All-Element Tester | $10,000 - $11,000 |

VRAY VR-S7 | Benchtop Jewelry Tester | $7,000 - $10,000 |

Model Type & Portability: Unit type (desktop, handheld, benchtop) and portability define core design, components, and price.

Detector Technology: Si-PIN detector type/origin (standard, customized, US-sourced) impacts sensitivity, accuracy, and cost.

Elemental Range & Accuracy: Elemental range (gold-only vs. F-U) and accuracy (e.g., 0.003 for 9999 gold) drive pricing differences.

Features & Integration: Advanced features (built-in PCs, X-ray tube type, safety) add to unit value and price.

Manufacturer Expertise: VRAY's 17 years of expertise guarantees quality, reliability, and innovation, reflected in pricing.

Accuracy, on the other hand, refers to how close a measured value is to the true or actual value of the jewelry's composition. For a Jewelry Checking Machine, this means if a piece of gold is genuinely 18K (75% gold), an accurate machine will report a value very close to 75.0%. VRAY Jewelry Checking machines boast impressive accuracy specifications, such as 0.1% for gold (VR-X5) and 0.003 for 9999 gold (VR-H5, VR-S7). This exceptional accuracy is achieved through the integration of advanced technologies like high-performance Si-PIN proportional detectors (in VR-X5) and customized Si-PIN detectors (in VR-H5, and US-sourced in VR-S7), which precisely capture the characteristic X-ray signals. Furthermore, our machines utilize a stable PDT (50 KV) full mirror-focused tungsten X-ray tube and a precise Φ0.8mm collimator, ensuring optimal excitation and targeted analysis. The stable operating environment, supported by dedicated T-shaped heat dissipation without external cooling, also contributes to consistent detector performance. Achieving high accuracy is paramount in the jewelry industry to prevent misrepresentation, ensure fair trade, and provide correct valuations for precious metals. While precision indicates reproducibility, accuracy confirms the measurement's validity against the true composition, minimizing systematic errors and ensuring reliable identification of metal purity and type.

Operating a VRAY Jewelry Checking Machine is a straightforward process designed for efficiency and accuracy. Follow these steps for proper usage:

Power On: Turn on the machine and then open its dedicated software application.

Instrument Preheating: Allow the instrument to preheat for approximately 10 minutes. This stabilizes the internal components for accurate readings.

Calibration: Place the designated calibration sample in the detection area and perform the instrument calibration as prompted by the software. This ensures measurement accuracy.

Sample Placement: After successful calibration, carefully place the actual jewelry sample you wish to analyze into the detection area.

Initiate Test: Close the machine's cover securely and press the "start" button to begin the analysis.

Await Results: The machine will now perform the analysis. Generally, a preliminary analysis result will be displayed within 3 seconds, with the complete, final analysis result available in approximately 30 seconds.

Print/Save Report: Once the test is completed, select the "Print" icon to generate a report. You have the option to print an A4 report or use a Bluetooth thermal printer. Alternatively, you can save the report digitally without immediate printing.

Proper maintenance is crucial for ensuring the longevity, accuracy, and consistent performance of your VRAY Jewelry Checking Machine. Adhere to these routine maintenance practices:

Daily Cleaning: Wipe the outer shell of the machine with a clean, soft, or lint-free cloth every day to prevent the accumulation of dust and debris.

Test Window Inspection: Before each use, visually inspect the test window (detector film) for any foreign objects, contamination, or smudges. Keep it impeccably clean and transparent to ensure accurate X-ray penetration and signal detection.

Regular Fan and Vent Cleaning: Clean the machine's fans and ventilation outlets regularly. This prevents blockages that can lead to overheating and ensures efficient cooling of internal components.

Environmental Control: Maintain the room temperature between 15-30°C and humidity below 70%. Avoid exposure to excessive moisture or direct sunlight, as these conditions can negatively impact the sensitive electronics.

Voltage Stability: Always use a voltage stabilizer or an Uninterruptible Power Supply (UPS) to protect the machine from unstable voltage, which can damage critical components like the X-ray tube and motherboard.

Avoid Prolonged High-Load Use: While VRAY machines are designed for efficiency, avoid prolonged continuous high-load operation. It's advisable to allow the machine to rest periodically or turn off its internal cooling (if applicable, or simply allow internal components to cool down) after extended use to prevent overheating and prolong component lifespan.

At VRAY, we understand that reliable performance of your Jewelry Checking Machine is paramount. Backed by our extensive industry experience, we offer robust technical support and swift emergency response solutions, ensuring your operations run smoothly and efficiently.

VRAY provides a full spectrum of proactive and responsive technical assistance for your Jewelry Checking Machine:

Installation Instructions: We provide clear, detailed installation instructions to facilitate the seamless and rapid setup of your new VRAY Jewelry Checking Machine, ensuring it becomes operational with minimal fuss.

Software Updates: Our commitment to innovation means continuous improvement. We deliver regular software updates and upgrades for your Jewelry Checking Machine's operating system, enhancing features, improving analytical algorithms for even greater accuracy, and ensuring long-term compatibility and performance. These updates can often be deployed remotely for your convenience.

Technical Training: To empower our customers, VRAY offers comprehensive technical training sessions. These sessions cover all aspects of operating your Jewelry Checking Machine, including proper calibration techniques, sample preparation, result interpretation, and best practices to maximize its efficiency and analytical precision. Training can be tailored to your team's needs.

Hardware Warranty: Every VRAY Jewelry Checking Machine is backed by a robust hardware warranty, providing peace of mind against manufacturing defects. This commitment ensures that your investment is protected, guaranteeing reliable operation and component integrity.

Remote Guidance: Our expert technical team is always ready to provide real-time remote guidance. Utilizing secure remote access tools, we can assist with troubleshooting, operational queries, and minor adjustments for your Jewelry Checking Machine, ensuring immediate support wherever you are.

VRAY is fully equipped to handle critical issues, minimizing downtime and swiftly restoring the functionality of your Jewelry Checking Machine:

Problem: Software glitches, system crashes, or failed updates can severely impede the operation of your Jewelry Checking Machine, affecting its analytical capabilities and output.

Solution: VRAY maintains a dedicated team of highly skilled engineers available for immediate remote support. They can quickly diagnose and resolve software conflicts, reconfigure settings, or facilitate necessary updates and upgrades, often getting your Jewelry Checking Machine back online within minutes or hours, thus ensuring continuous workflow.

Problem: Critical hardware component failures can render your Jewelry Checking Machine inoperable or compromise its safety features, requiring expert intervention.

Solution 1: Expedited Parts & Remote Assistance: For specific hardware component failures that are user-replaceable (like certain sensors or modules), VRAY can swiftly mail genuine replacement accessories. This is combined with comprehensive video tutorials and real-time remote guidance from our engineers, empowering customers to perform quick and effective component swaps on their Jewelry Checking Machine, significantly reducing repair times and associated costs.

Solution 2: On-Site Engineer Dispatch: For more complex hardware issues or when remote solutions are insufficient, VRAY is prepared to dispatch experienced field engineers directly to your site. Our technicians will conduct a thorough on-site diagnosis and perform the necessary repairs, guaranteeing expert intervention and comprehensive restoration of your Jewelry Checking Machine's full functionality and safety standards.

What did our happy clients say?

The VRAY VR-H5 Jewelry Checking Machine delivers unparalleled 0.003 accuracy for 9999 gold, analyzing ALL(F-U) elements across solid/liquid/powder. Its versatility is crucial for our comprehensive appraisal lab, ensuring precise valuations. A truly professional-grade instrument.

For our busy retail and pawn operations, the VRAY VR-X5 Jewelry Checking Machine is indispensable. Its 0.1% gold accuracy and 10s test time streamline every transaction. Results are consistently reliable, building immense customer trust. Highly recommend for high-volume environments!

As a mobile buyer, the VRAY VR-K5 handheld Jewelry Checking Machine is perfect. Its 0.003 accuracy for 9999 gold and 20s test time are invaluable on-site. The portability and robust build mean reliable results anywhere. An essential tool for field work.

Investing in a VRAY Jewelry Checking Machine was a strategic decision. The consistent accuracy and advanced XRF technology truly protect our business from misidentification losses. Excellent ROI, backed by reliable performance and great manufacturer support. A top-tier professional tool.