An XRF (X-ray Fluorescence) machine is a powerful analytical instrument that uses X-ray technology to precisely determine the elemental composition of materials, non-destructively. At VRAY, we design our XRF machines, like the VR-H5 handheld model, to leverage this principle for accurate and efficient analysis across various applications, from gold purity testing to metal identification.

Understanding the operational steps of an XRF machine is key to appreciating its efficiency and accuracy. Here's a detailed breakdown of how a VRAY XRF machine works, from initial setup to final results:

One of the significant advantages of XRF technology is the minimal sample preparation required. For most solid samples, like a piece of jewelry, a metal alloy, or a mineral specimen, you simply need to ensure the surface is clean and free from any major contaminants (like heavy dirt, grease, or thick paint) that could interfere with the X-ray interaction. For powders or liquids, specialized cups or film might be used, but the core material remains untouched.

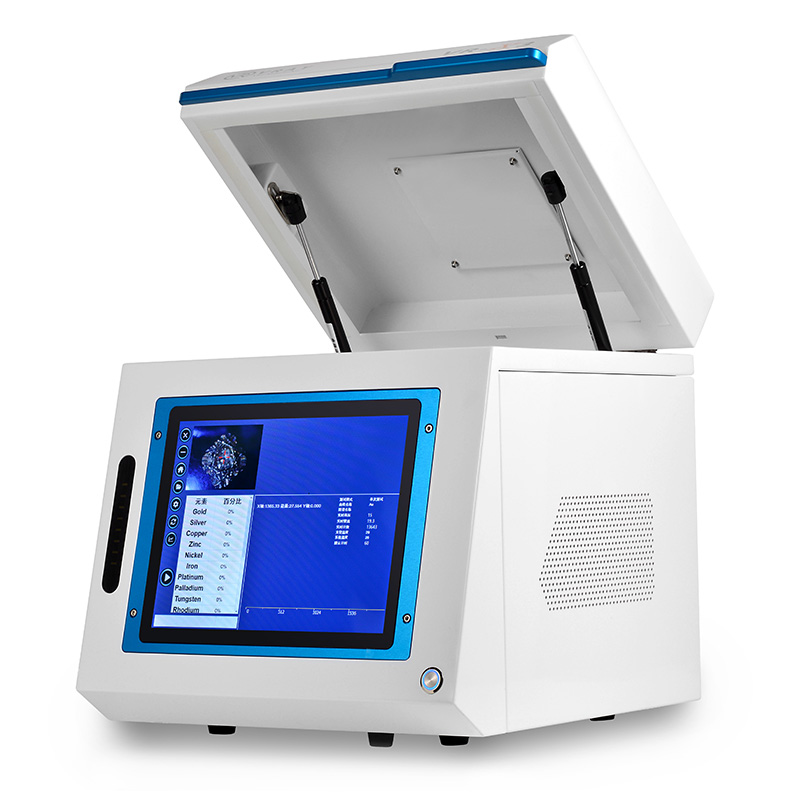

Once the sample is ready, it's carefully placed into the XRF machine's designated testing area. For handheld units like the VRAY VR-H5, the measurement window is typically placed directly onto the surface of the item. For benchtop models, the sample is positioned within a closed chamber. Proper placement ensures that the X-ray beam is directed accurately onto the sample, and that the detector can effectively capture the emitted fluorescent X-rays.

After the sample is positioned and the test initiated (usually by pressing a "Start" or "Trigger" button on the intuitive touch screen, like the 4.3" industrial resistive touch screen on the VRAY VR-H5), the XRF machine's internal X-ray tube activates. This tube generates and emits a controlled beam of primary X-rays towards the sample.

When these primary X-rays strike the atoms within the sample, they possess enough energy to knock out electrons from the inner orbital shells of those atoms. This creates an unstable state for the excited atoms. To regain stability, electrons from higher energy shells immediately "fall" into the vacant inner-shell positions. As these electrons drop to a lower energy state, they release excess energy in the form of secondary, "fluorescent" X-rays. Crucially, the energy of these emitted fluorescent X-rays is unique and characteristic to the specific element from which they originated. Every element has its own distinct "fingerprint" of X-ray energies.

The fluorescent X-rays emitted from the sample travel towards the XRF machine's detector. VRAY XRF machines utilize high-performance detectors, such as the customized Si-Pin detector from USA found in the VR-H5, which are designed to accurately measure the energy and count the number of these incoming fluorescent X-rays.

The detector transmits the information (energy and intensity of each X-ray photon) to the XRF machine's internal processor. Sophisticated software algorithms then analyze this data:

Elemental Identification: By identifying the specific energies of the fluorescent X-rays, the software determines which elements are present in the sample.

Concentration Quantification: By measuring the intensity (number) of the X-rays for each identified element, the software calculates its concentration within the sample. Higher intensity for a particular element means a higher concentration.

Result Display: The results are then displayed on the machine's screen, typically showing a list of detected elements with their respective percentage concentrations. For applications like gold testing, the karat value is also instantly calculated and shown. This entire process, from excitation to result display, is incredibly fast, often taking just 30 seconds for a precise measurement with the VR-H5.

After the analysis, users can typically save the results to the machine's internal memory (VRAY VR-H5 boasts 32GB of memory), generate reports, or transfer the data to a computer or other device via USB or Bluetooth for further analysis, record-keeping, or certification purposes.

At VRAY, our commitment is to provide XRF machines that are not only technologically advanced but also user-friendly and reliable. Our 17 years of manufacturing experience ensure that each unit is built for accuracy and durability, empowering you with precise elemental analysis.