Below is a video overview of how to use XRF machine, watch it carefully to learn more!

VRAY offers a comprehensive portfolio of XRF Machine solutions, designed to meet diverse analytical needs across various industries, from precious metal analysis to industrial quality control and environmental screening. Our machines combine cutting-ed

ge technology with user-friendly interfaces, ensuring high performance and reliability.

Key product lines and their solutions include:

Solutions: Ideal for on-the-go analysis in diverse environments. The VR-H5 is ultra-light (1.6kg) with an 8-hour battery, perfect for rapid Positive Material Identification (PMI), scrap metal sorting, or on-site gold testing. The VR-M5 offers enhanced portability (4.1kg) with a larger screen and built-in camera, providing more detailed visual data for field applications.

Applications: Perfect for identifying alloys in manufacturing, ensuring safety in construction (e.g., lead paint detection), geological mapping, environmental compliance, and rapid precious metal valuation in pawn shops or during mobile buying.

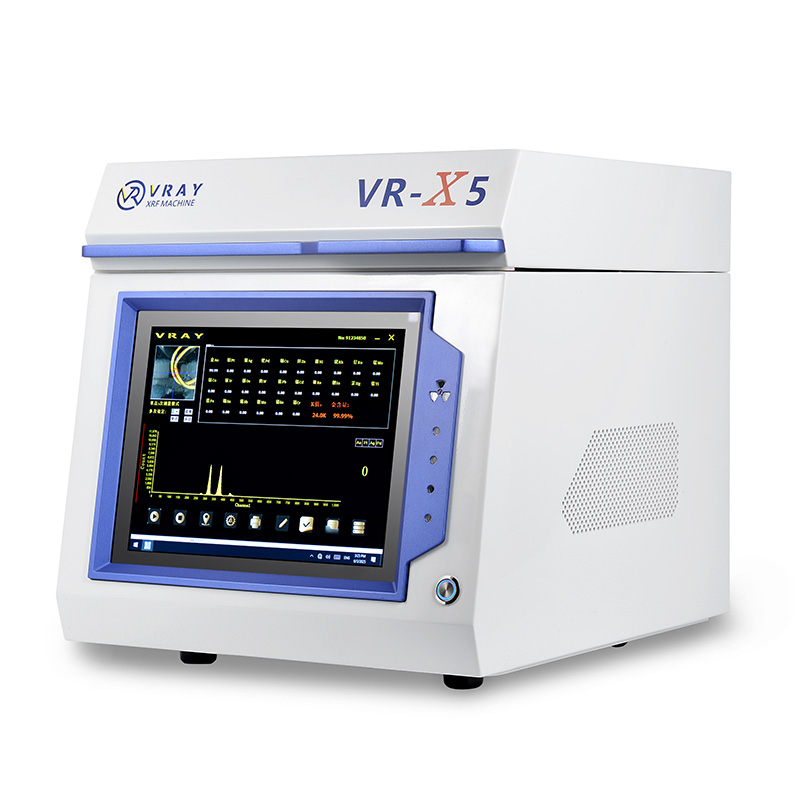

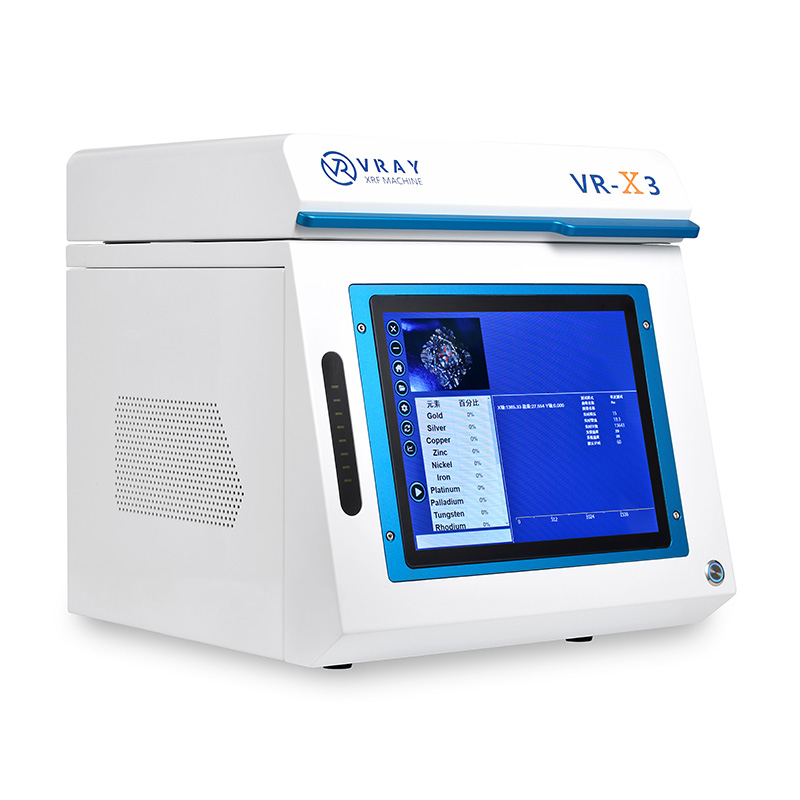

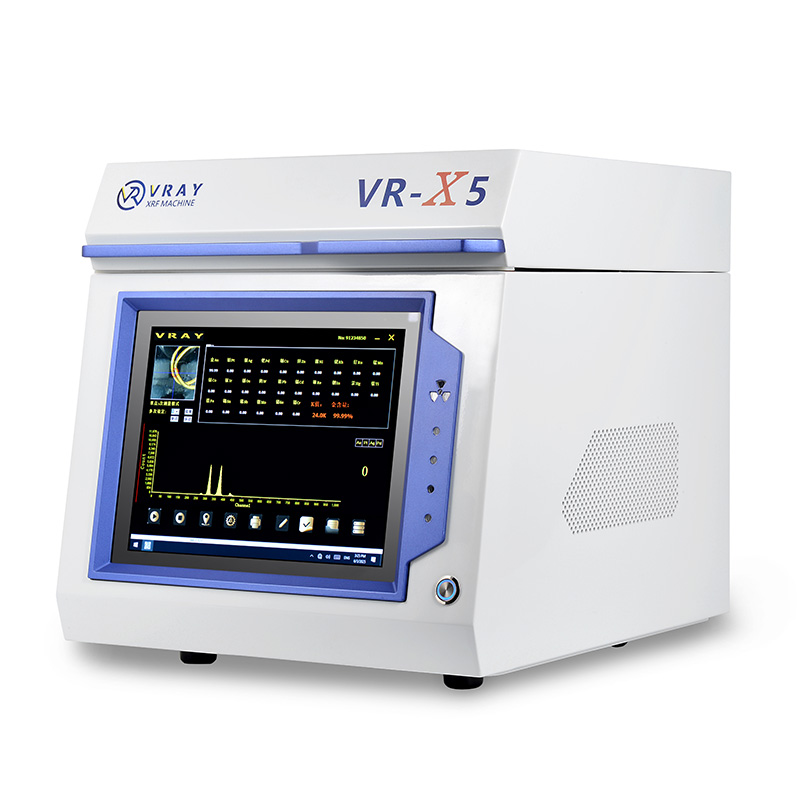

Solutions: These stationary units provide superior precision and are often equipped with higher-sensitivity detectors (like SDD detectors for sub-trace level analysis). They feature larger sample chambers, integrated computers, and advanced software for in-depth analysis. Models like the VR-T7 offer manual XY platforms and high-magnification cameras for micro-area analysis, while the VR-S7 provides a powerful all-in-one workstation.

Applications: Crucial for precious metal assaying (e.g., high-accuracy gold and jewelry testing), RoHS/WEEE compliance testing in electronics, quality control in manufacturing (e.g., alloy verification, coating thickness measurement), academic research, and analysis of diverse sample types including powders, liquids, and thin films in laboratory settings.

VRAY's XRF Machines are built with a focus on safety, durability, and intuitive operation, ensuring that users can achieve accurate and efficient elemental analysis for their specific applications.

Sources

XRF (X-ray Fluorescence) is a powerful, non-destructive technique for determining elemental composition. Its working principle involves several key steps:

X-ray Emission: An XRF Machine generates a controlled beam of high-energy primary X-rays, directed at the sample.

Atomic Excitation: These primary X-rays strike atoms in the sample. If their energy is sufficient, they dislodge an electron from an atom's inner orbital shell, creating an unstable "hole."

Fluorescent X-ray Emission: To stabilize, an electron from a higher-energy outer shell drops to fill the inner-shell vacancy. This transition releases excess energy as a secondary, "fluorescent," X-ray. The energy of this emitted X-ray is unique and characteristic to the specific element, acting as its "atomic fingerprint."

Detection and Analysis: A specialized detector in the XRF Machine captures these fluorescent X-rays, measuring both their energy and intensity.

Elemental Identification & Quantification: The machine's software processes this data. By identifying the characteristic X-ray energies, it determines which elements are present (qualitative analysis). By measuring the intensity, it quantifies their concentration (quantitative analysis), typically displayed as percentages or ppm.

Using an XRF Machine is typically straightforward, allowing for rapid, non-destructive elemental analysis. Follow these steps for efficient and safe operation:

Preparation & Safety: Power on the XRF Machine and let it complete its self-diagnostics. Always prioritize safety; ensure the X-ray beam is pointed away from people. For handheld units, guarantee full contact with the sample to prevent scatter.

Sample Cleaning: Gently clean the sample surface. Remove any dirt, grease, or thick coatings that could interfere with the X-ray interaction, ensuring the most accurate results.

Select Mode: Choose the appropriate analytical "mode" or "calibration" on the machine's interface. This could be "Alloy," "Precious Metals," or "RoHS," tailored to your specific analysis.

Sample Placement: For handheld models, press the XRF Machine's analysis window firmly against the sample. For desktop units, securely place the sample inside the chamber and close the door, engaging safety interlocks.

Initiate Analysis: Pull the trigger on handheld models or press the "Start" button on desktop software. The test usually takes seconds to a minute. Keep the machine steady and maintain contact or ensure the chamber remains closed during this period.

Interpret & Manage Results: View the elemental composition and any alloy identification displayed on the screen. Save the data for records and export it via USB, Wi-Fi, or Bluetooth for reporting or further analysis as needed.

What did our happy clients say?

The VR-H5 Handheld XRF Machine is a game-changer for our mobile testing needs in Flint Hill! Weighing only 1.6kg with an 8-hour battery life, its portability is unmatched. The customized Si-Pin detector provides accurate readings down to 0.03% for gold, crucial for our scrap metal business. Highly recommended for anyone needing reliable on-site analysis!

Our lab in Toronto loves the VR-S7 All-in-one Desktop XRF Machine. The integrated Windows 11 PC and 11.6" touchscreen make it incredibly user-friendly. Its SDD detector delivers exceptional accuracy, achieving 0.01% for 9999 gold. This powerful XRF machine has significantly improved our precious metal analysis workflow. A must-have!

The VR-M5 Portable XRF Machine is the perfect balance of power and mobility for our geological surveys in the Australian outback. Its 5.7" retractable screen and built-in 5MP camera aid in sample documentation. The Si-Pin detector offers reliable elemental analysis, making it invaluable for on-site mineral identification. Strongly recommend this robust machine!

We invested in the VR-T7 Desktop XRF Machine for our jewelry manufacturing in London, and it's been outstanding. The manual XY platform and high-resolution 5MP camera with 160x magnification allow precise analysis of intricate pieces. The SDD detector's 0.01% accuracy ensures the quality of our alloys. This top-tier XRF machine is an essential investment for any serious jeweler!