Below is a video overview of How to Use XRF Tester, watch it carefully to learn more!

VRAY offers a comprehensive range of XRF Tester solutions, meticulously designed to provide fast, accurate, and non-destructive elemental analysis across various materials and industries. Our XRF Testers are built with advanced technology to ensure reliable results whether in the lab, factory, or field.

For handheld and portable applications, VRAY's VR-H5 and VR-M5 models stand out. The VR-H5 is an ultra-lightweight handheld XRF Tester at just 1.6kg (with battery), featuring a customized Si-Pin detector for quick and precise analysis. Its 4.3" industrial resistive touchscreen and 8-hour battery life make it ideal for prolonged on-site use, such as scrap metal sorting, PMI, or field exploration. The VR-M5 offers enhanced portability at 4.1kg, boasting a larger 5.7" retractable color touchscreen and a built-in 5-megapixel HD camera for clearer sample visualization and documentation, perfect for applications requiring slightly more detailed on-site work like advanced alloy identification or gold testing.

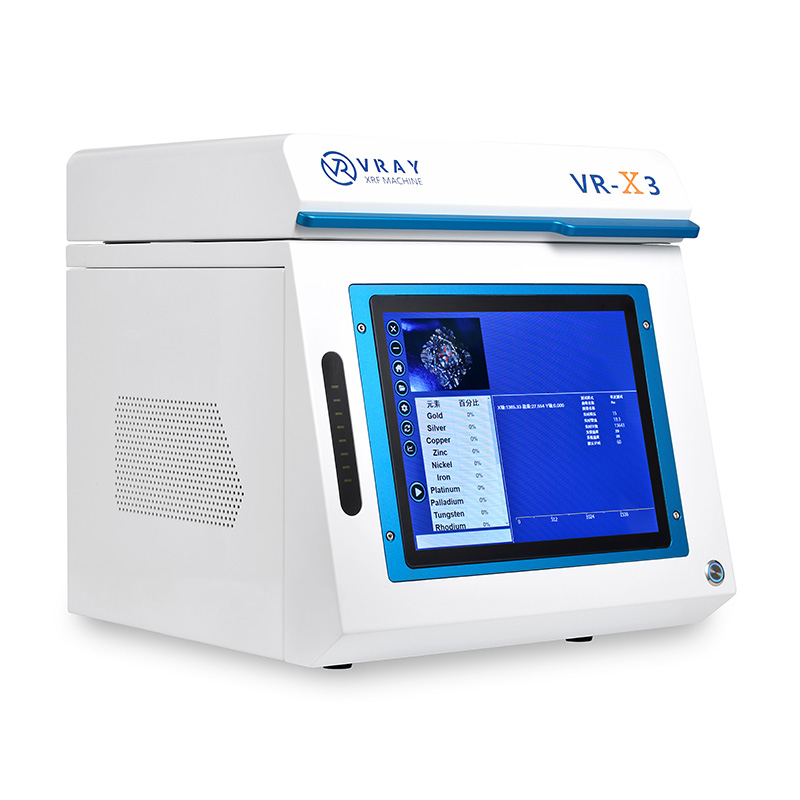

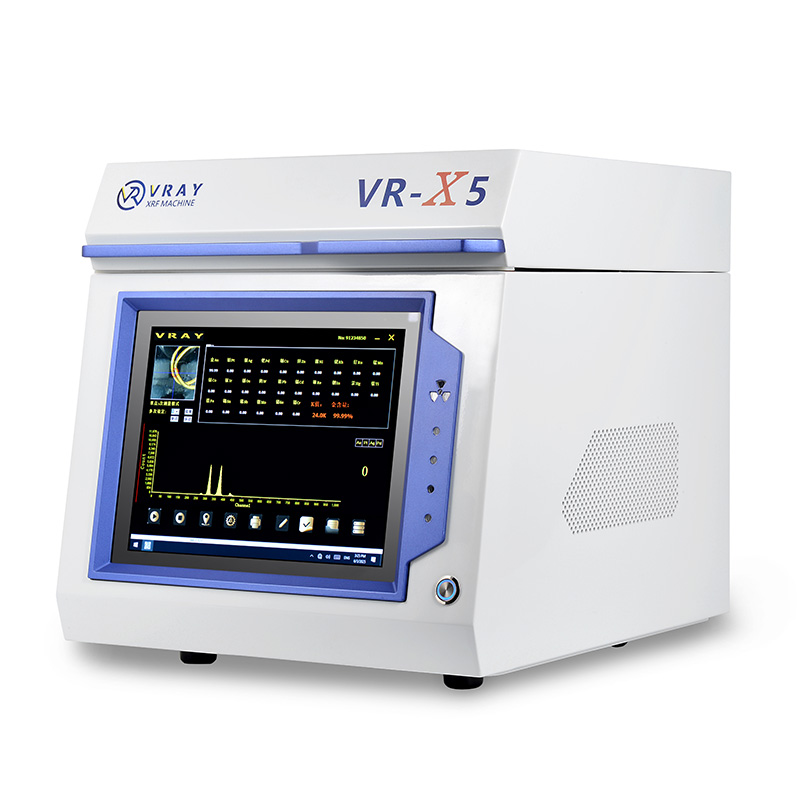

Our desktop XRF Testers cater to applications demanding the highest precision and integrated functionalities. The VR-S7 and VR-T7 represent our top-tier desktop solutions, equipped with high-sensitivity SDD detectors for superior accuracy (e.g., 0.01% for 9999 gold on precious metals). The VR-S7 integrates an 11.6" touchscreen and an inbuilt i5-1035G7 Windows 11 computer for a powerful, all-in-one analytical workstation. The VR-T7 further excels with its manual XY platform and high-resolution 5MP camera with 40x-160x magnification, enabling precise micro-analysis and detailed inspection. For more cost-effective or entry-level desktop needs, models like VR-X3, VR-X5, VR-S6, and VR-T6 provide reliable XRF analysis with various levels of features and accuracy, suitable for diverse quality control and material verification tasks. All VRAY XRF Testers are engineered for durability, user-friendliness, and compliance with safety standards.

VRAY provides a diverse selection of XRF Testers, categorized by their design and specialized uses:

Features: These are lightweight, highly portable, and battery-powered, offering rapid, on-site analysis. They come with robust Si-PIN or SDD detectors and intuitive touchscreen interfaces for fast results within seconds.

Applications: Perfect for scrap metal sorting, Positive Material Identification (PMI), geological exploration, environmental screening, and on-site precious metal analysis (functioning as a Gold Tester Gun).

Features: While still easily movable, these are slightly larger than typical handhelds. They often include enhanced features like bigger screens or integrated cameras.

Applications: They bridge the gap between handheld and desktop units, making them ideal for tasks requiring mobility within a facility.

Features: These stationary units deliver higher precision, often featuring advanced SDD detectors, larger sample chambers, and integrated computing. Some offer micro-spot analysis and vacuum systems for light element analysis.

Applications: Best suited for laboratory environments, manufacturing quality control, R&D, precious metal assaying, RoHS compliance testing, and analyzing powders, liquids, or thin films. They frequently serve as XRF Gold Analyzers, XRF Precious Metal Analyzers, or general XRF Metal Analyzers.

Using an XRF Tester involves a few straightforward steps, designed for efficiency and safety:

Preparation: Ensure the XRF Tester is powered on and has completed its internal self-checks. For handheld units, check battery levels. The sample surface should be as clean as possible, free from dirt, grease, or coatings that might interfere with the X-ray interaction. For desktop units, place the sample securely within the sample chamber.

Safety First: Always prioritize safety. Ensure you understand and follow the manufacturer's safety guidelines. For handheld XRF Testers, keep the analysis window pointed away from yourself and others, and ensure the sample is flush against the window when testing. Desktop units typically have interlocks that prevent X-ray emission if the chamber door is open.

Sample Placement: Position the sample directly against the XRF Tester's measurement window. For handheld units, this means pressing the gun firmly against the material. For desktop models, place the sample flat in the designated area inside the chamber.

Select Test Mode/Calibration: Choose the appropriate analysis mode or calibration for your material (e.g., "Alloy," "Precious Metals," "Soil," "RoHS"). Modern XRF Testers have pre-calibrated methods for common applications.

Initiate Analysis: Pull the trigger (for handheld) or press the "Start" or "Analyze" button on the software interface. Hold the unit steady (handheld) or keep the chamber closed (desktop) for the duration of the test, which typically takes a few seconds to a minute depending on the required precision and elements.

Interpret Results: The XRF Tester will display the elemental composition (e.g., percentage of Fe, Cu, Au) and often an alloy identification or pass/fail result directly on its screen. Review the data.

Data Management: Save the results, generate reports (many VRAY models allow custom reports with company logos), and export data via USB, Bluetooth, or Wi-Fi as needed for record-keeping or further analysis.

What did our happy clients say?

The VR-T7 Desktop XRF Tester is a lab essential. Its 0.01% accuracy for 9999 gold with the SDD detector is incredibly precise, and the manual XY platform allows for exact positioning on tiny samples. This XRF tester consistently provides reliable, high-resolution elemental analysis. Absolutely vital for our quality control!

Our team relies on the VR-H5 Handheld XRF Tester daily. Weighing just 1.6kg with an 8-hour battery life, it's perfectly portable for scrap metal sorting. The customized Si-Pin detector gives us 0.03% accuracy on various alloys quickly. This XRF tester makes on-site material identification fast and dependable.

The VR-S7 All-in-one Desktop XRF Tester has streamlined our R&D. Its integrated Windows 11 PC and 11.6" touchscreen make it super user-friendly. The SDD detector delivers 0.01% accuracy across a broad elemental range (K to U). It’s a powerful, compact XRF tester that truly enhances our analytical capabilities.

We’re very impressed with the VR-M5 Portable XRF Tester. Its 4.1kg weight is easy to manage, and the 5.7" retractable screen with a 5MP camera is excellent for visual sample verification. The Si-Pin detector provides solid 0.05% accuracy for general metal analysis. This XRF tester is a robust and highly practical solution for field use.