Below is a video overview of Machine For Gold Testing by VRAY, watch it carefully to learn how to use a Machine For Gold Testing!

Gold Tester

| Gold Testing Machine

| XRF Analyzer

| XRF Spectrometer

|

Machines For Gold Testing, primarily utilizing X-ray Fluorescence (XRF) technology, are versatile tools with critical applications across various industries where accurate gold and precious metal analysis is essential.

Jewelry and Precious Metal Retail: Jewelers and pawn shops use these machines for immediate, non-destructive authentication and accurate karat determination of gold, silver, platinum, and palladium items, ensuring fair pricing for both buyers and sellers.

Gold Refining and Recycling: Refineries employ XRF Gold Testing Machines to quickly assess the purity of incoming scrap gold, ore, and bullion at various stages of the refining process. This maximizes precious metal recovery and ensures the quality of the final product.

Gold Prospecting and Mining: In the field, portable gold testers allow geologists to analyze gold content in soil, rock, and ore samples, helping to identify economically viable deposits and make informed decisions on excavation.

Customs and Border Security: Authorities use XRF Gold Analyzers to quickly screen gold shipments and detect counterfeit items or undeclared precious metals, combating smuggling and ensuring trade compliance.

Manufacturing Quality Control: Manufacturers of gold components or plated items use gold testing machines to verify alloy composition, coating thickness, and identify contaminants, ensuring product quality and compliance with specifications.

Financial Institutions and Bullion Dealers: Banks and bullion traders utilize these machines for gold testing to verify the authenticity and purity of gold bars, coins, and other investment-grade gold products, mitigating fraud risks.

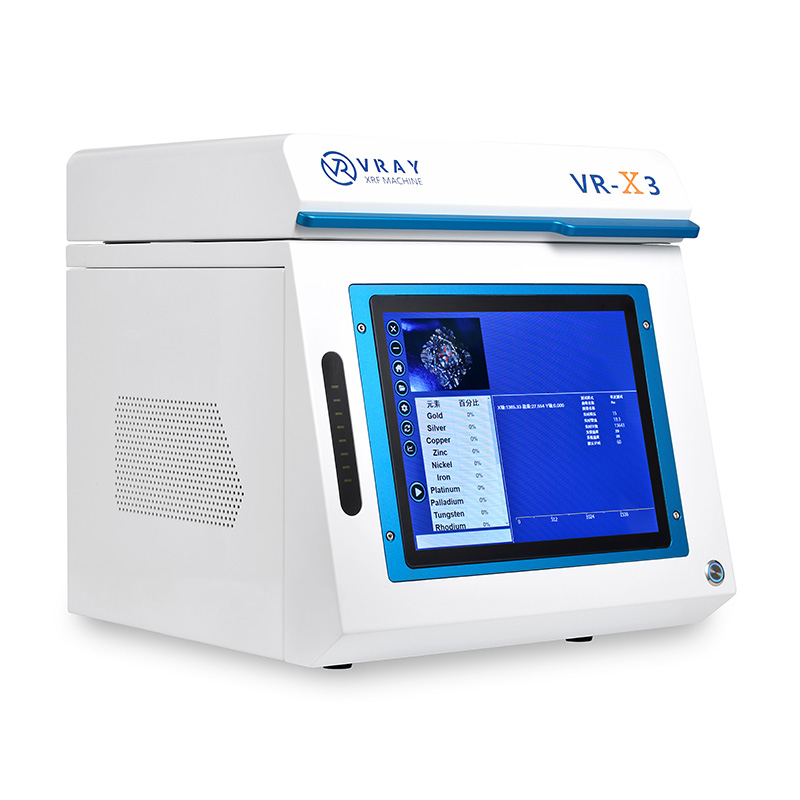

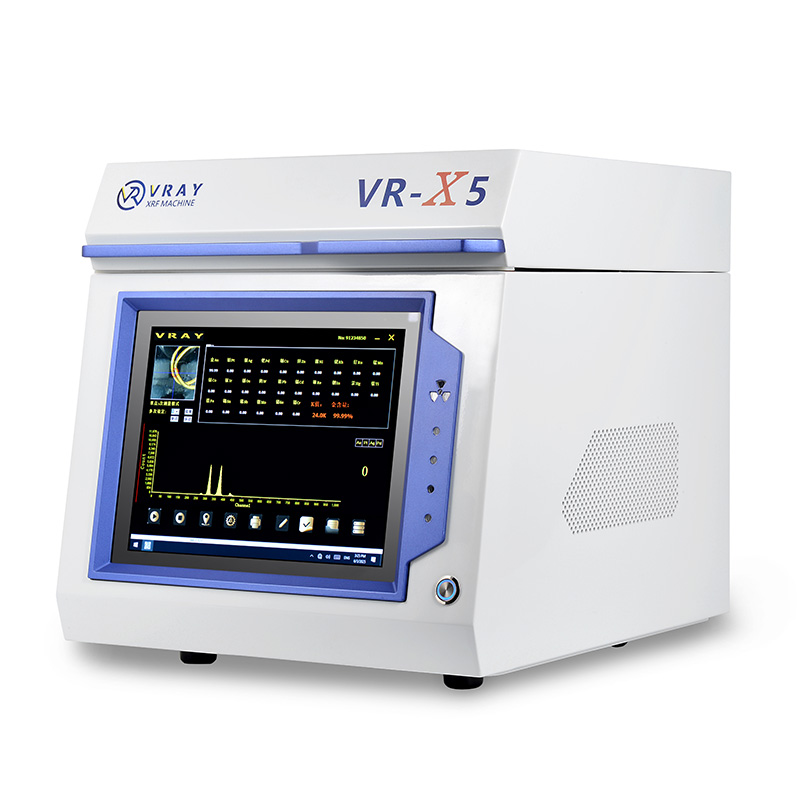

Machines For Gold Testing (XRF Gold Testers) are sophisticated instruments designed for precise elemental analysis.

Non-Destructive Analysis: A paramount feature, ensuring the integrity and value of the gold item are preserved during testing.

Rapid Results: Provides instant purity readings (karatage) and elemental composition within seconds, significantly increasing workflow efficiency.

High Accuracy & Precision: Modern XRF Gold Testing Machines (e.g., VRAY's SDD detector models) offer high accuracy, often down to 0.01% for 9999 gold, ensuring reliable valuation.

Multi-Elemental Detection: Capable of identifying and quantifying not only gold but also common alloying elements like silver, copper, nickel, zinc, and other precious metals like platinum, palladium, and rhodium. Some can detect elements from Mg to U.

User-Friendly Interface: Equipped with intuitive touchscreens and software for easy operation, calibration, and data management.

Portability Options: Available in handheld gold tester (e.g., VRAY VR-H5) for on-site use or desktop XRF analyzer (e.g., VRAY VR-S7) for laboratory-grade precision.

Data Management & Connectivity: Features like internal storage, USB, Bluetooth, and Wi-Fi allow for data saving, export, and report generation.

Safety Features: Built-in radiation shielding, interlocks, and automatic shut-off mechanisms ensure operator safety.

Coating/Plating Detection: Many models can detect and sometimes measure the thickness of gold plating, distinguishing between solid gold and plated items.

The fundamental working principle of an XRF Gold Tester is X-ray Fluorescence.

X-ray Emission: The machine for gold testing (specifically, its X-ray tube) emits a controlled beam of high-energy primary X-rays onto the surface of the gold sample.

Atomic Excitation: When these primary X-rays strike atoms within the sample, they can dislodge electrons from the inner orbital shells of these atoms.

Fluorescent X-ray Emission: To regain stability, an electron from a higher energy outer shell fills the vacancy in the inner shell. As this electron drops to a lower energy state, it emits a secondary (fluorescent) X-ray. The energy of this emitted X-ray is unique and characteristic to the specific element from which it originated, acting like an atomic "fingerprint."

Detection and Analysis: A specialized detector within the XRF Analyzer captures these fluorescent X-rays. The detector measures their energies and intensities.

Elemental Identification & Quantification: The gold testing machine's internal software analyzes the spectrum of detected X-rays. By identifying the characteristic energies, it determines which elements are present (qualitative analysis). By measuring the intensity of each element's characteristic X-rays, it quantifies their concentration (quantitative analysis), which is then translated into gold purity (karatage) and other alloy percentages.

What did our happy clients say?

The VR-T7 Desktop Machine For Gold Testing is simply unmatched. Its 0.01% accuracy for 9999 gold, thanks to the SDD detector, gives us absolute confidence in our high-value bullion. The manual XY platform and 160x camera magnification are essential for micro-analysis. This Machine For Gold Testing is a powerful tool for serious refiners. Highly recommended!

For mobile gold buying, the VR-H5 Handheld Machine For Gold Testing is phenomenal. At just 1.6kg with an 8-hour battery, it's incredibly practical. The customized Si-Pin detector delivers 0.03% accuracy, providing quick and reliable karat readings on the spot. This Machine For Gold Testing is robust, accurate, and a vital part of our daily operations. Can't recommend enough!

The VR-S7 All-in-one Desktop Machine For Gold Testing transformed our jewelry workshop. Its integrated Windows 11 PC and 11.6" touchscreen make operation seamless. We consistently get 0.01% accuracy for 9999 gold with its SDD detector. It’s a fast, precise, and user-friendly Machine For Gold Testing that’s a true asset for any jeweler.

We chose the VR-M5 Portable Gold Tester for its balance of accuracy and portability. Weighing 4.1kg, it’s easy to move between benches, and the 5.7" retractable screen is a huge plus. The Si-Pin detector offers solid 0.05% accuracy for 9999 gold. This gold testing machine is a reliable workhorse for our varied testing needs. Strongly endorse it!