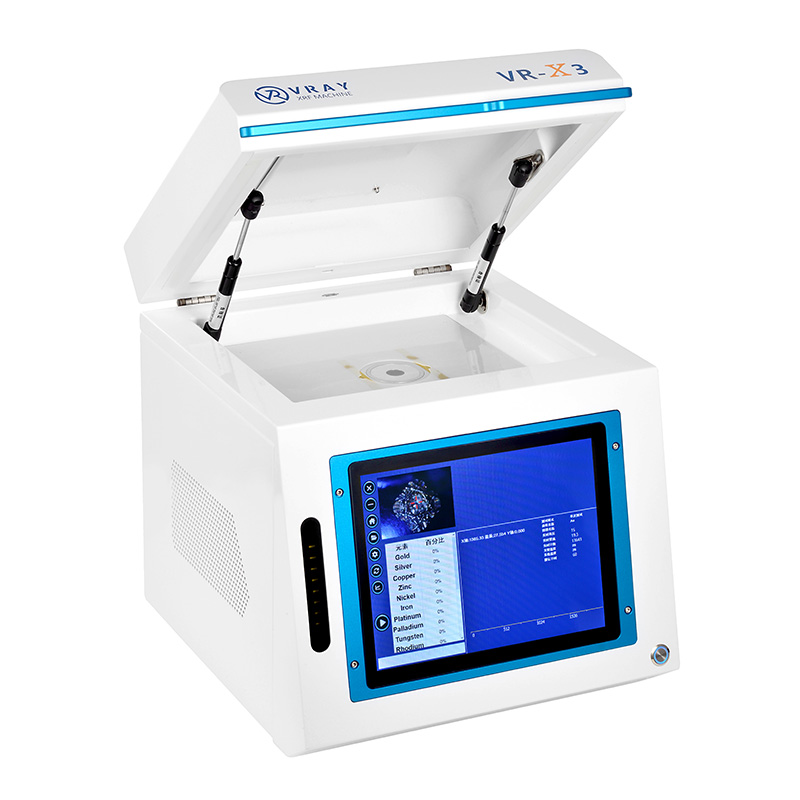

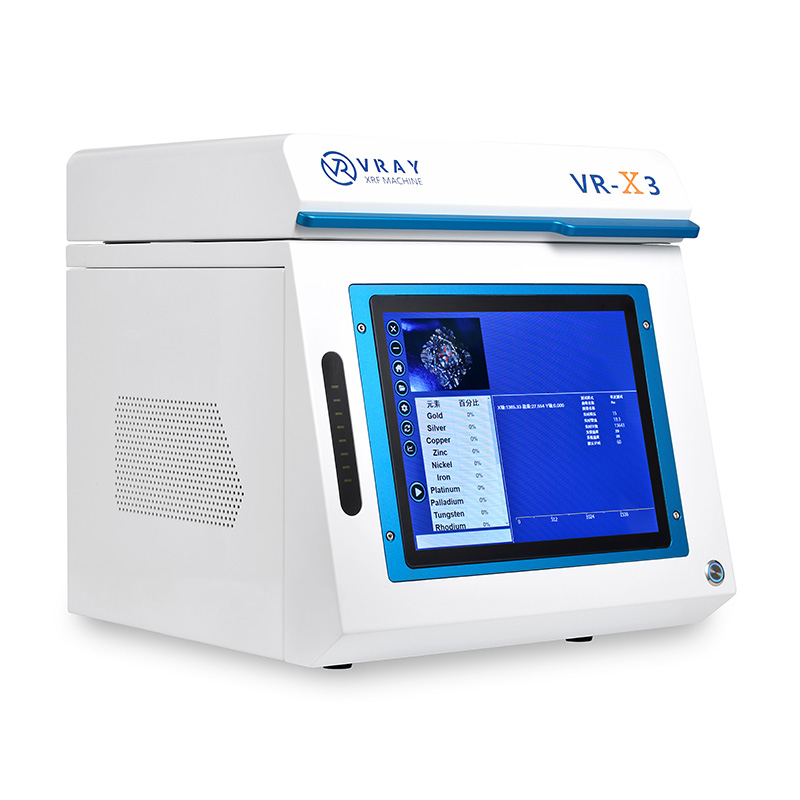

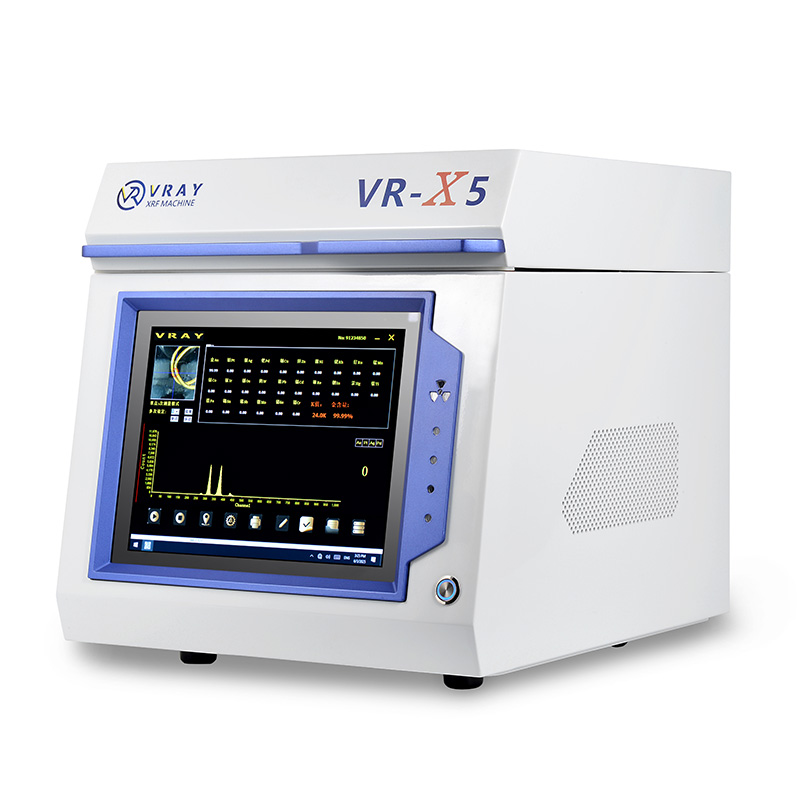

With 17 years of manufacturing expertise, VRAY offers advanced XRF Spectrometer For Gold solutions, catering to diverse analytical needs from rapid retail checks to high-precision lab analysis. Our comprehensive portfolio, featuring models like the compact VR-X3, the versatile VR-X5, and the lab-grade VR-T7, provides non-destructive elemental composition analysis specifically for gold and other precious metals.

These spectrometers integrate cutting-edge technical solutions such as specialized detectors (Proportional, Customized Si-Pin, High-sensitivity SDD), powerful DET 50KV X-ray tubes, and adjustable collimators (φ 1.5mm to 2.5mm) for optimized excitation and detection. Key functional features across our range include rapid test times (as low as 30s), exceptionally high accuracy (up to 0.01% for 9999 gold), broad elemental analysis capabilities (from Au, Ag, Pt, Pd, Rh, Cu, Zn, Ni to K-U92), and user-friendly interfaces with integrated computers. VRAY's solutions are engineered for unparalleled reliability, precision, and efficiency in all gold testing applications.

An XRF Spectrometer For Gold non-destructively identifies and quantifies elemental composition. It works by exciting samples with primary X-rays, causing gold and its alloys to emit unique fluorescent X-rays, which are then precisely measured.

Accuracy is paramount. VRAY's spectrometers offer superior precision: VR-T7 achieves 0.01% for 9999 gold (High-sensitivity SDD, φ 1.5mm collimator); VR-X5 offers 0.05% for 999 gold (Customized Si-Pin); VR-20 provides 0.1% for 999 gold (Proportional detector).

Advanced Detectors: SDD/Si-Pin detectors enhance signal resolution.

Rigorous Calibration: Daily use of certified gold standards is crucial for consistent results.

Optimized X-ray Source: DET 50KV tubes with adjustable parameters and specific targets (Ag, Au, W, Rh) ensure optimal gold excitation.

Precision Collimation: Finer collimators improve X-ray beam focus, reducing noise.

Sample Preparation: Clean, flat surfaces minimize interference.

Environmental Stability: Operating within 10℃-35℃ maintains detector stability.

VRAY's integrated technology and best practices ensure highly reliable gold analysis.

Using a VRAY XRF Spectrometer For Gold is designed for efficiency and ease, ensuring accurate results:

Initial Setup & Warm-up: Connect the spectrometer to power. For optimal stability, allow the instrument to warm up (e.g., 10 minutes).

Daily Calibration: At the beginning of each testing session, perform a quick calibration using a certified gold standard sample. Follow the on-screen prompts for guided setup.

Sample Placement: Place your gold item (solid, liquid, or powder) securely within the designated testing chamber (e.g., VR-X5: 270x270x100mm, VR-S7: 240x160x120mm). Ensure the sample surface is clean and flat for best results.

Initiate Test: Close the safety chamber door to engage the interlock. On the integrated display (e.g., 11.6" touchscreen for VR-S7 or 4.3" for VR-H5), select the appropriate test mode and initiate the analysis.

Result Display: The spectrometer will conduct a rapid analysis (e.g., 30-50 seconds) and instantly display the elemental composition and karatage on the screen.

Data Management: You can then save, print, or export the test data via USB or Bluetooth for record-keeping and reporting.

The price of an XRF Spectrometer For Gold varies by model and capability. VRAY's range includes the compact VR-X3 at $6,000-$7,000; the versatile VR-X5 (desktop) at $10,000-$11,000; and the high-precision lab-level VR-T7 at $20,000-$22,000.

Accuracy & Precision: Paramount for gold analysis. Look for specific accuracy (e.g., 0.01% for 9999 gold) and advanced detectors (High-sensitivity SDD).

Test Speed: Faster analysis (e.g., 30s for VR-S7) optimizes workflow.

Elemental Range: Ensure it covers gold, its common alloys, and relevant elements (K-U92).

Sample Versatility: Confirm capability for your sample forms (solid/liquid/powder) and appropriate chamber size.

Portability vs. Benchtop: Match the form factor to your operational environment.

Safety & Support: Verify X-ray safety features and robust manufacturer after-sales service (warranty, training, technical support).

To ensure optimal performance and extend the lifespan of your VRAY XRF Spectrometer For Gold, please adhere to these operational precautions:

Daily Start-up Protocol: Strictly preheat and calibrate the instrument after its first activation each day.

Safety First: Always commence testing with the protective door securely closed to prevent any X-ray leakage.

Power Stability: It is highly recommended to use a regulated power supply or an Uninterruptible Power Supply (UPS) to guard against voltage fluctuations, which can damage the X-ray tube and mainboard.

Environmental Control: Maintain a dry, clean, and well-ventilated working environment for the equipment, actively avoiding high temperatures and excessive humidity (ideally, room temperature should be between 15-30°C and humidity below 70%).

Software Integrity: Always strictly follow the official operation manual or the manufacturer's training guidelines; refrain from privately modifying software parameter settings.

Regular Cleaning: Daily wipe the outer casing with a clean, soft, lint-free cloth to prevent dust accumulation. Before each use, inspect the test window for any foreign objects or contamination and ensure it remains clean and transparent. Regularly clean the fans and vents to prevent blockages and overheating.

Avoid Overload: Prevent prolonged continuous high-load usage; incorporate regular cooling intervals to enhance the machine's longevity.

Improper operation or unexpected circumstances can lead to malfunctions or safety hazards with your XRF Spectrometer For Gold. VRAY provides solutions for various emergency scenarios:

Radiation Exposure Risk: Initiating a test when the protective door is not tightly closed can result in X-ray leakage and potential radiation harm to the operator. Similarly, moving the sample or opening the door during an active test can lead to X-ray exposure.

Hardware & System Damage: Forcibly cutting off power or frequently cycling the machine on and off can easily damage the X-ray tube, high-voltage module, or hard disk, potentially causing a system crash.

Environmental Malfunctions: Operating the device in humid, hot, or excessively dusty environments can lead to overheating, mainboard dampness, and detector malfunction or short-circuit.

Software/Data Corruption: Unauthorized modification of software parameters or calibration data can distort analysis data, which may necessitate returning the software to the factory for recalibration. This also includes general software issues such as the software becoming unusable or failing during updates/upgrades.

Detector Damage: Touching the highly sensitive detector window (e.g., the SDD protection window) with sharp objects or fingers can cause irreparable damage to the detector film, leading to extremely high maintenance costs.

Core Hardware Failures: Specific component failures, including damage to the X-ray tube, detector failure, abnormal high-voltage power module operation, or protective door sensor malfunction.

Our dedicated VRAY engineers are available to provide remote support at any time to diagnose and resolve software-related problems for our customers.

Mail Accessories & Video Tutorials: Customers have the option to receive necessary replacement accessories, accompanied by detailed video tutorials, to facilitate guided self-repair where applicable.

On-site Engineer Dispatch: For more complex or critical hardware malfunctions, VRAY can dispatch qualified engineers directly to the customer's site to diagnose and resolve the problem in person.

What did our happy clients say?

Our recent upgrade to the VRAY XRF Spectrometer For Gold (VR-S7) is phenomenal! Its 0.01% accuracy for 9999 gold and 30s test time are unparalleled for lab-level analysis. The High Sensitivity SDD ensures extreme precision. Truly a professional-grade instrument. Highly recommended for any serious lab!

We've just integrated the VRAY XRF Spectrometer For Gold (VR-X5), and it's perfect for our pawnshop. Its 0.05% accuracy for 999 gold and Customized Si-Pin detector give us immense confidence in pricing. The 40s test time and solid/liquid/powder range make it incredibly versatile. A fantastic all-in-one solution!

My recent purchase of the VRAY XRF Spectrometer For Gold (VR-X3) has been excellent. Its compact 2Kg design and wireless feature are ideal for my small jewelry store. The 0.1% accuracy for 999 gold is more than sufficient for instant authentication. Great value for money, truly boosts customer trust. Strongly recommend!

Our latest investment in the VRAY XRF Spectrometer For Gold (VR-S7) is remarkable! The 11.6" touchscreen and φ 1.5mm collimator ensure detailed analysis. With 0.01% accuracy and 30s tests, our quality control is flawless. A top-tier machine for serious manufacturers. Absolutely satisfied!