What the video below to learn how to use an XRF equipment

VRAY offers a comprehensive range of XRF Equipment solutions, meticulously designed to provide precise, non-destructive elemental analysis for diverse applications. Our XRF machines are built with advanced technology, ensuring high performance, reliability, and user-friendliness across various industries.

VRAY VR-H5 Handheld XRF Analyzer (XRF Gun):

Type: Ultra-portable, pistol-grip handheld XRF.

Weight: Extremely lightweight at 1.6kg (with battery), designed for extended field use.

Detector: Features a high-performance, customized Si-Pin detector from USA, ensuring excellent elemental separation and accuracy.

X-ray Tube: Powerful 50KV/200μA (adjustable) X-ray tube with a durable tungsten (W) target.

Accuracy: Achieves 0.03% accuracy for 9999 gold (for precious metals mode).

Screen: Intuitive 4.3" industrial resistive touch screen.

Battery Life: Approximately 8 hours of continuous operation per battery, with intelligent power management.

Data Storage/Transfer: 32GB internal memory, USB, Bluetooth, and WIFI connectivity for seamless data transfer and remote support.

Safety Features: Equipped with active radiation protection and a gravity sensing system for automatic shutdown upon falling.

Ideal for: Scrap metal sorting, Positive Material Identification (PMI), geological exploration, and on-site gold/precious metal analysis.

VRAY VR-M5 Portable XRF Analyzer:

Type: Enhanced portable XRF, balancing mobility with advanced features.

Weight: 4.1kg, still highly transportable for various field applications.

Detector: Utilizes a high-performance, imported Si-Pin detector from USA.

X-ray Tube: Up to 50KV/200μA with a tungsten target, providing 4W max excitation power.

Accuracy: Offers 0.05% accuracy for 9999 gold.

Screen: Larger 5.7" foldable color touch screen for improved visibility.

Camera: Built-in 5-megapixel high-definition CMOS color camera for detailed sample imaging.

Data/Connectivity: Ample storage, USB, Bluetooth, WIFI connectivity, and internet connection for remote services.

Ideal for: On-site precious metal testing, general metal alloy identification, and applications requiring better sample visualization.

VRAY VR-T7 Desktop XRF Analyzer (Flagship Precision):

Type: High-precision, laboratory-grade desktop XRF.

Detector: Features a top-tier high-sensitivity SDD (Silicon Drift Detector), enabling ultra-low detection limits and superior elemental separation.

X-ray Tube: Powerful 50W (50 kV, 1mA) micro-focused beryllium window X-ray tube.

Collimator: Fine ϕ1.5mm collimator for precise spot analysis.

Accuracy: Unparalleled 0.01% accuracy for 9999 gold, offering the highest level of precious metal purity verification.

Sample Chamber: Spacious 320 x 480 x 130mm chamber with a manual XY sample platform.

Camera: 5-million-pixel high-resolution CMOS color camera with 40x-160x magnification for detailed visual inspection and precise sample targeting.

Ideal for: High-volume precious metal assaying, research & development, and quality control requiring ultimate accuracy and micro-analysis capabilities.

VRAY VR-S7 All-in-one Desktop XRF Analyzer (Integrated High-Precision):

Type: Compact, integrated high-precision desktop XRF.

Detector: Equipped with a high-sensitivity SDD detector for excellent analytical performance.

Accuracy: Delivers 0.01% accuracy for 9999 gold.

Integrated PC: Features an inbuilt Intel i5-1035G7 Windows 11 computer for a seamless, standalone workstation.

Screen: Large 11.6" integrated touchscreen for intuitive control.

Ideal for: Jewelers, refiners, and labs needing a compact, high-accuracy XRF solution with integrated computing.

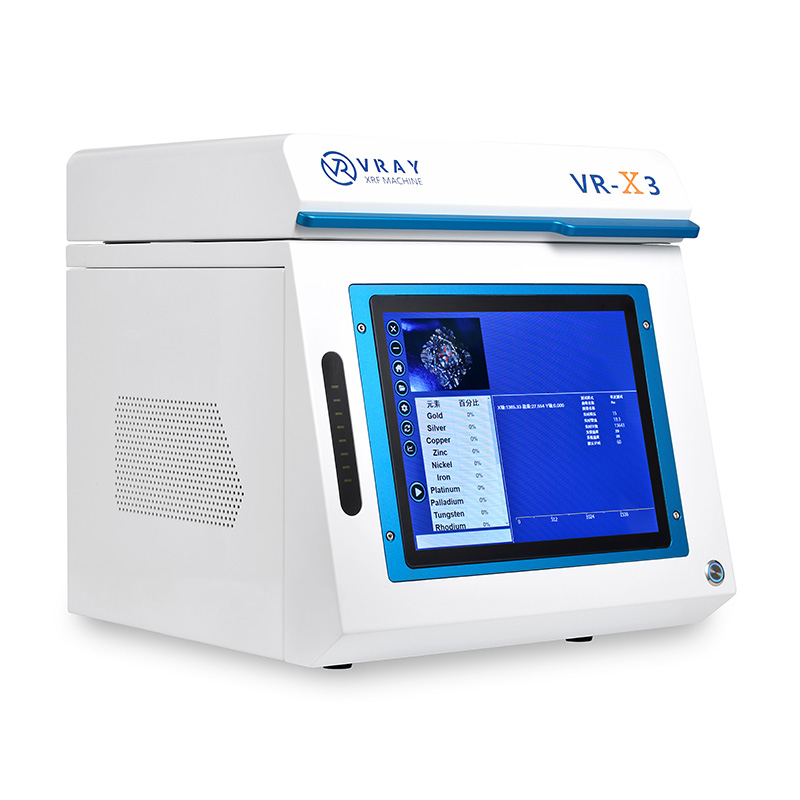

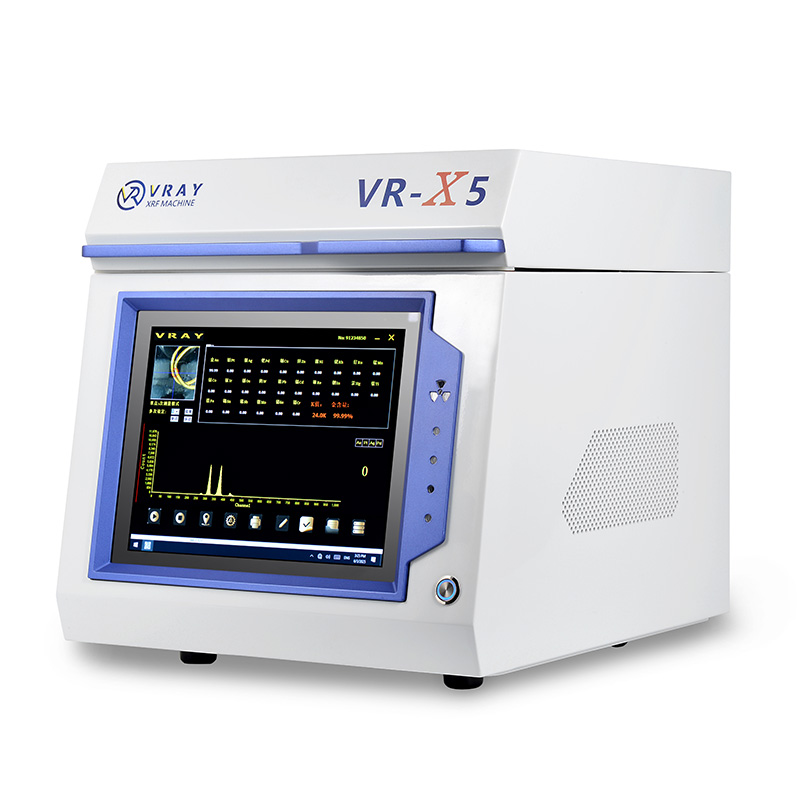

VRAY VR-X5 All-in-one Desktop XRF Analyzer (Value-Oriented Desktop):

Type: Cost-effective, integrated desktop XRF.

Detector: Uses a customized Si-Pin detector, offering reliable performance.

Accuracy: Provides 0.05% accuracy for 9999 gold.

Integrated PC: Features an inbuilt Intel i5 3320M computer for a complete system.

Price Point: Typically in the $10,000-$11,000 range, offering excellent value.

Ideal for: General precious metal analysis, basic quality control, and educational purposes where high precision is required on a budget.

VRAY VR-T6 Desktop XRF Analyzer:

Type: Reliable desktop XRF tester.

Detector: Features a customized Si-Pin detector from USA.

Accuracy: Offers 0.03% accuracy for 9999 gold.

Integrated PC & Screen: Inbuilt i5-1035G7 Windows 11 computer and an 11.6" touchscreen.

Ideal for: Consistent gold and alloy testing in a desktop environment.

VRAY VR-S6 Mini Desktop XRF Analyzer:

Type: Compact desktop XRF solution.

Detector: Employs a customized Si-Pin detector from USA.

Accuracy: Provides 0.03% accuracy for 9999 gold.

Integrated PC & Screen: Features an inbuilt i5-1035G7 Windows 11 computer and an 11.6" touchscreen.

Ideal for: Workspaces with limited space that still require accurate and reliable precious metal analysis.

XRF (X-ray Fluorescence) is a powerful, non-destructive technique for elemental composition. An XRF Machine operates in these key steps:

X-ray Emission: The XRF Equipment's X-ray tube generates a controlled beam of primary X-rays directed at the sample.

Atomic Excitation: These primary X-rays dislodge inner-shell electrons from sample atoms if their energy is sufficient, making the atoms unstable.

Fluorescent X-ray Emission: To stabilize, an electron from a higher-energy outer shell fills the inner-shell vacancy. This transition releases energy as a unique, secondary "fluorescent" X-ray—each element's "atomic fingerprint."

Detection & Analysis: A specialized detector in the XRF Machine captures these fluorescent X-rays, measuring their energy and intensity.

Elemental Identification & Quantification: The machine's software processes this data. By identifying characteristic X-ray energies, it determines which elements are present (qualitative analysis). By measuring intensity, it quantifies their concentrations (quantitative analysis), typically displayed as percentages or ppm. This rapid process provides accurate material characterization.

XRF Equipment is widely used across various industries due to its versatility and analytical capabilities:

Quality Control & Material Identification (PMI): Essential in manufacturing, aerospace, and oil & gas for verifying alloy grades, ensuring material conformity, and preventing critical failures due to material mix-ups.

Scrap Metal Sorting & Recycling: Rapidly identifies and sorts various metal alloys from mixed scrap, maximizing recycling value and ensuring proper segregation.

Precious Metal Analysis: Indispensable for jewelers, refiners, and pawn shops for non-destructive gold testing, karat verification, and analysis of silver, platinum, and palladium.

Mining & Geological Exploration: Portable XRF Equipment is used on-site to analyze ore, soil, and rock samples, helping identify mineral deposits, delineate ore bodies, and make quick decisions.

Environmental Monitoring: Rapidly screens soil, water, and air filter samples for heavy metal contamination, aiding in site remediation and environmental compliance.

RoHS/WEEE Compliance: Used in electronics manufacturing to test for hazardous substances (e.g., Lead, Cadmium, Mercury, Cr, Br) in components and finished products, ensuring regulatory compliance.

Art & Archaeology: Non-destructively analyzes the elemental composition of artworks, artifacts, and historical objects to determine authenticity, origin, and restoration needs.

Consumer Product Safety: Used to screen consumer goods for regulated toxic elements (e.g., lead in toys).

XRF Equipment offers significant advantages for elemental analysis, driven by its powerful features:

Non-Destructive Testing: The paramount benefit; analysis occurs without altering or damaging the sample, crucial for valuable items or finished products.

Rapid & Accurate Results: Provides instant purity readings and elemental composition, often within seconds. High-end XRF Machines like VRAY's VR-T7 offer 0.01% accuracy for 9999 gold, ensuring reliable data.

Multi-Elemental Analysis: Capable of simultaneously identifying and quantifying a wide range of elements, from magnesium (Mg) to uranium (U), including all common alloying elements.

User-Friendly Operation: Modern XRF Equipment features intuitive touchscreen interfaces and software, minimizing training time and simplifying analysis.

Versatile Form Factors: Available as handheld XRF analyzers (e.g., VR-H5) for on-site mobility or robust desktop XRF analyzers (e.g., VR-T7) for laboratory-grade precision.

Cost-Effective: Reduces the need for time-consuming and destructive traditional lab tests, saving both time and material.

Enhanced Safety: Built-in radiation shielding, interlocks, and automated shutdown mechanisms ensure operator safety during use.

Advanced Data Management: Offers ample internal storage, with options for data export via USB, Bluetooth, or Wi-Fi, facilitating seamless integration into existing data systems and customizable report generation.

Using an XRF Equipment is generally straightforward, prioritizing both efficiency and safety.

Preparation & Safety: Power on the XRF Machine and allow it to self-calibrate. Always follow safety guidelines; never point the X-ray beam at people. For handheld units, ensure the analysis window is firmly against the sample to prevent scatter. Desktop units have safety interlocks.

Sample Cleaning: Gently clean the sample surface, removing any dirt, grease, or thick coatings that could interfere with X-ray interaction, ensuring accurate results.

Select Mode: Choose the appropriate analytical mode or calibration on the XRF Equipment's interface (e.g., "Alloy," "Precious Metals," "RoHS").

Sample Placement: For handheld models, press the XRF Machine's analysis window firmly against the sample. For desktop units, place the sample securely inside the chamber and close the door.

Initiate Analysis: Pull the trigger (handheld) or press "Start" (desktop software). Hold steady or keep the chamber closed for the test duration (seconds to minutes).

Interpret & Manage Results: View the elemental composition and alloy ID on the screen. Save the data for records and export via USB, Wi-Fi, or Bluetooth for reporting or further analysis.

What did our happy clients say?

The VR-T7 Desktop XRF Equipment is a powerhouse! Its SDD detector delivers phenomenal 0.01% accuracy for 9999 gold, making our refinery's purity checks foolproof. The manual XY platform and 160x camera magnification are invaluable for precise micro-analysis. This XRF machine is an absolute necessity for top-tier quality control. Strongly recommended!

Our team in Glasgow relies solely on the VR-H5 Handheld XRF Equipment. At just 1.6kg with an 8-hour battery, its portability is unmatched for on-site scrap sorting. The customized Si-Pin detector consistently provides 0.03% accurate alloy identification in seconds. This XRF gun is robust, reliable, and revolutionizes our workflow. Highly endorse it!

The VR-S7 All-in-one Desktop XRF Equipment transformed our jewelry analysis in Toronto. Its integrated Windows 11 PC and 11.6" touchscreen make operation incredibly smooth. The SDD detector provides 0.01% accuracy across all precious metals, ensuring meticulous verification. This compact XRF machine is simply the best for a modern lab. A definitive recommendation!

We chose the VR-M5 Portable XRF Equipment for its excellent balance of features for our geological fieldwork in Mexico City. Weighing 4.1kg, it’s easily transportable, and the 5.7" retractable screen with a 5MP camera is fantastic for documenting samples. The Si-Pin detector delivers consistent, accurate elemental data. This XRF machine is durable and incredibly practical for diverse applications.