XRF Mineral Analyzer solutions by VRAY offer unparalleled precision and versatility for geological, mining, and environmental analysis. Our lineup caters to diverse needs, from rigorous field exploration to advanced laboratory research, built on 17 years of dedicated manufacturing expertise.

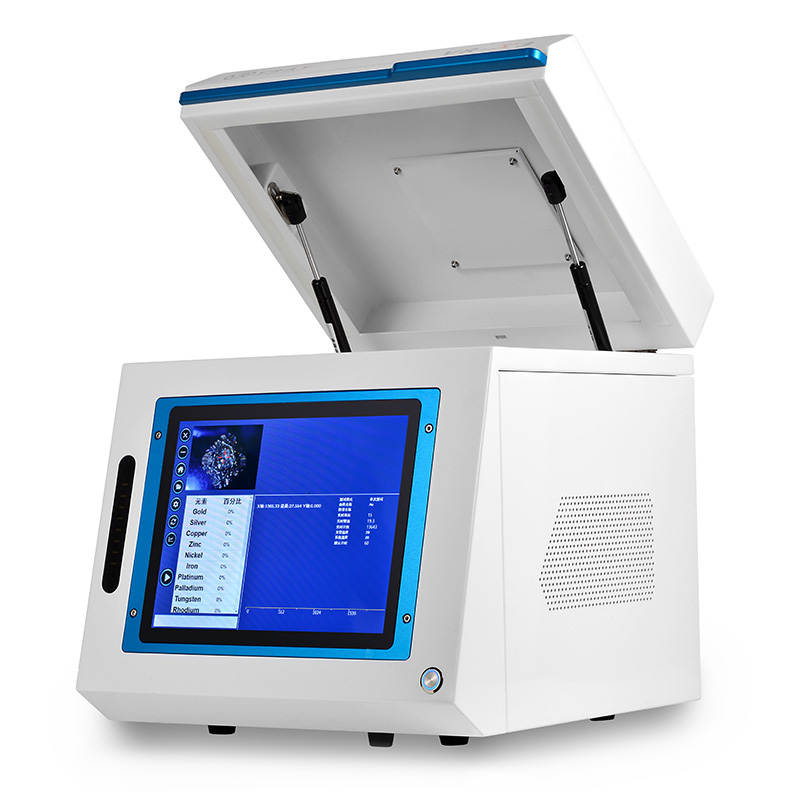

Leading our high-precision offerings is the VR-S7, an all-in-one desktop analyzer engineered for ultimate accuracy. Boasting an exceptional 0.01% accuracy for 9999 gold (reflecting its superior capability for trace elements), it features a high-sensitivity SDD detector and a precise ϕ1.5mm collimator. Powered by a 50W beryllium window X-ray tube and integrated with an i5 Windows 11 PC on an 11.6" touchscreen, the VR-S7 delivers rapid 30-second tests across a broad K(19)~U(92) element range for solid, liquid, or powder samples in demanding lab environments.

For dynamic field-based analysis without compromising accuracy, VRAY offers the VR-M5 and VR-H5 portable XRF Mineral Analyzers. The VR-M5 is a robust portable unit (4.1Kg) providing 0.05% accuracy with its Si-Pin detector and a 5.7" retractable touchscreen, ideal for versatile on-site material verification. The VR-H5 is our lightest handheld solution (1.6Kg), delivering impressive 0.03% accuracy with its Si-Pin detector and up to 8 hours of battery life, perfect for rapid mineral identification directly at exploration sites or mines. Both portable models excel with solid, liquid, or powder samples in 30 seconds.

Across all models, VRAY integrates core technologies like efficient T-shaped radiators for "no cooling wait" performance, ensuring consistent operation. Our extensive experience allows for flexible hardware (e.g., adjustable X-ray tube targets, collimator size) and software customization (analysis modes, calibration algorithms, multi-language interfaces), providing optimized tools for precise mineral exploration, quality control, and compliance.

An XRF Mineral Analyzer offers rapid, non-destructive elemental analysis, vital for geosciences and mining. It solves critical challenges like lengthy lab delays, enabling immediate decision-making. Key solutions include precise on-site mineral identification, real-time ore grade control, and efficient geochemical mapping for optimized exploration and production. Its core applications include:

Mining & Exploration: Essential for identifying new deposits, evaluating ore bodies, and performing grade control from drill cores to mill feed.

Geological Surveys: Used for detailed geochemical analysis of rock and soil, aiding in mapping and understanding formations.

Environmental Monitoring: Applied in assessing soil and water contamination, particularly for detecting heavy metals in mining areas, supporting compliance.

Process Optimization: Enables real-time adjustments in mineral processing plants to improve recovery rates and overall efficiency.

High-Performance Detectors: Equipped with high-sensitivity SDD detectors (VR-S7) or customized Si-Pin detectors from the USA (VR-M5, VR-H5), ensuring exceptional elemental detection.

Unrivaled Accuracy: Achieve industry-leading precision, with accuracy as fine as 0.01% for 9999 gold (VR-S7), translating to highly reliable mineral and elemental quantification.

Rapid Analysis: All models boast a fast 30-second test time, enabling quick decision-making in the field or lab.

Broad Elemental Range: Detects elements from Potassium (K, 19) to Uranium (U, 92) in advanced models (e.g., VR-S7), covering a vast array of minerals.

Robust X-ray Source: Feature 50W micro-focused X-ray tubes (e.g., beryllium window for VR-S7, adjustable options for VR-H5).

Versatile Portability: Offer both truly handheld (VR-H5, 1.6Kg, 8-hour battery) and portable (VR-M5) options, alongside high-end desktop units (VR-S7).

Intuitive User Interface: Equipped with high-resolution touchscreens (e.g., 11.6" on VR-S7 with inbuilt i5 PC, 5.7" retractable on VR-M5), built-in cameras (VR-M5), and seamless data transmission via USB or Bluetooth.

Efficient Cooling System: Integrated T-shaped radiators ensure optimal heat dissipation, preventing overheating and eliminating cooling wait times.

Non-Destructive Elemental Analysis: Provides precise elemental composition without damaging samples.

Real-time Mineral Identification & Ore Grade Control: Allows for immediate assessment of mineral types and concentration in drill cores, rocks, and soils.

Geochemical Mapping: Supports rapid analysis for mapping elemental distributions in geological surveys.

Material Verification & Quality Control: Ensures consistency and compliance of mineral products and raw materials.

Contamination Detection: Identifies heavy metals and other pollutants in environmental geological samples.

Sample Versatility: Capable of analyzing various sample types including solids, liquids, and powders, catering to diverse application needs.

| Price and Cost of XRF Mineral Analyzer | Purchase Considerations |

|---|---|

The cost of an XRF Mineral Analyzer from VRAY varies significantly based on the model, detector type, and features. As a direct manufacturer, VRAY offers competitive factory pricing. VR-S7 (Desktop): $20,000 - $22,000 VR-M5 (Portable): $15,000 - $18,000 VR-H5 (Handheld): $15,000 - $18,000 | Application Needs: What is the primary use (e.g., field exploration, lab QC, specific element analysis)? |

| Portability vs. Desktop: Do you require a handheld (VR-H5), portable (VR-M5), or fixed desktop (VR-S7) unit? | |

| Required Accuracy: What level of precision is critical for your analysis (e.g., 0.01% for VR-S7)? | |

| Elemental Range: Which specific elements or broad elemental coverage (K to U) do you need to detect? | |

| Sample Type: Will you be testing solids, liquids, powders, or a combination? | |

| Budget Alignment: Does the analyzer's price fit within your financial constraints? | |

| User Interface & Features: Desired screen size, presence of inbuilt PC, camera, and data transmission options. | |

| Environmental Conditions: Compatibility with typical operating temperature and humidity range. | |

| Battery Life (for portable/handheld): Importance of extended operation time for field work. | |

| Technical Support & Service: Availability of reliable after-sales support, including remote assistance. | |

| Customization Options: Do you require specific hardware or software adjustments for unique applications? | |

| Manufacturer Reputation: Experience and reliability of the supplier (VRAY has 17 years of experience). | |

Ensuring proper operation and adherence to safety guidelines is crucial for the accuracy, longevity, and safe use of your XRF Mineral Analyzer.

1. Power On & Software Launch: Turn on your XRF Mineral Analyzer, then launch its dedicated analytical software on the integrated or connected computer.

2. Instrument Preheating: Allow the instrument to preheat for approximately 10 minutes. This ensures the X-ray tube and detector stabilize, leading to more accurate and repeatable readings.

3. Calibration: Place the designated calibration sample (e.g., standard reference material) in the detection area. Follow the software prompts to perform accurate instrument calibration before analyzing unknown mineral samples.

4. Sample Placement: Carefully position your mineral sample (which can be in solid, liquid, or powder form) in the detection area according to the analyzer's manual and design. Ensure it's stable and covers the test window if applicable.

5. Close Cover & Start Test: Securely close the machine cover or protective door, ensuring all safety interlocks are engaged. Once confirmed, press the "start" button within the software to initiate the analysis.

6. Await Results & Report Management: Wait for the analysis results. Preliminary data typically appears in 3 seconds, with the complete analysis result available in approximately 30 seconds. After completion, you can print (e.g., A4 or thermal printer) or save the detailed report directly.

1. Safety Door Protocol: Always ensure the protective door or chamber cover is tightly closed and safety interlocks are engaged before and during any test. Never attempt to bypass these safety features, as this is critical to prevent X-ray leakage and radiation exposure.

2. Power Management: Avoid frequent power cycling (turning on/off rapidly) or forcibly cutting off power to the analyzer. Such actions can lead to severe damage to sensitive internal components like the X-ray tube, high-voltage module, and mainboard. Always use a voltage stabilizer or UPS (Uninterruptible Power Supply) to ensure stable power supply.

3. Environmental Control: Operate the XRF Mineral Analyzer in a controlled environment. Avoid high humidity (>70% non-condensing), excessive dust, or extreme temperatures outside the specified operating range (e.g., 10-35°C for desktop, -20-50°C for portable models). These conditions can cause overheating, dampness, or short-circuits.

4. No Unauthorized Modifications: Do not attempt to modify the analyzer's software, hardware, or internal calibration parameters privately. Unauthorized changes can lead to data distortion, component damage, and will void your warranty. Only qualified VRAY technicians should perform internal adjustments.

5. Detector Protection: Exercise extreme care with the detector window. Never touch it with fingers, sharp objects, or abrasive materials, as this can severely damage the thin detector film, leading to costly repairs and inaccurate readings.

6. Stable Testing Environment: Ensure the sample remains perfectly stationary and the chamber door remains closed throughout the test duration. Moving the sample or opening the door mid-test can result in test failure, inaccurate data, and potential X-ray exposure.

7. Regular Cleaning: Daily, gently wipe the analyzer's outer shell with a clean, soft, lint-free cloth to prevent dust accumulation. Before each use, inspect and clean the test window for any foreign objects or contamination to ensure clear and accurate readings.

8. Fan & Vent Maintenance: Regularly clean the analyzer's cooling fans and vents to prevent blockages from dust or debris, which can lead to overheating and affect instrument performance and lifespan.

9. Avoid Overload: Prevent prolonged continuous high-load use. Allow for regular rest periods and ensure the cooling system functions correctly to dissipate heat, extending the machine's lifespan and maintaining optimal performance.

10. Trained Personnel Only: Only properly trained and authorized personnel should operate the XRF Mineral Analyzer. Always strictly follow the manufacturer's user manual and safety guidelines to ensure safe and effective use.

What did our happy clients say?

Having recently acquired, the VRAY VR-S7 XRF Mineral Analyzer is unmatched. Its 0.01% accuracy with SDD detector across K-U range is critical for our lab. The 30s test and 11.6" i5 touchscreen boost efficiency. Highly recommend for high-precision mineral analysis.

We recently purchased the VRAY VR-H5 XRF Mineral Analyzer, transforming our field work. Its 0.03% accuracy at just 1.6Kg is astounding for a handheld. Combined with a 30s test and 8-hour battery, it's indispensable for rapid on-site analysis. A must-buy for serious exploration.

Having recently bought, our VRAY VR-M5 XRF Mineral Analyzer offers excellent versatility. Its 4.1Kg, 0.05% accuracy, and 5.7" retractable screen with camera make field work precise. It handles solid/liquid/powder samples in 30s effortlessly. An ideal portable solution. Highly recommended.

Recently acquired, the VRAY VR-H5 XRF Mineral Analyzer excels in harsh conditions. Its adjustable 50KV/200μA X-ray tube and -20℃ to 50℃ range ensure robust performance. Fast 30s testing across all sample types. This handheld unit is crucial for efficient geological surveys. Strongly endorse its reliability!